As per Intent Market Research, the Wire Harness Market was valued at USD 81.4 billion in 2023 and will surpass USD 134.2 billion by 2030; growing at a CAGR of 7.4% during 2024 - 2030.

The wire harness market plays a crucial role in a range of industries, from automotive to aerospace, telecommunications, and industrial manufacturing. Wire harnesses are critical components used for the transmission of electrical signals and power in a structured manner. These assemblies consist of a bundle of wires, connectors, and other components, ensuring the smooth functioning of electrical systems in vehicles, machinery, and electronics. With the rapid advancement of technologies, the wire harness market has seen substantial growth, driven by increasing demand for energy-efficient, high-performance, and reliable electrical systems. The market is segmented across various product types, end-user industries, materials, and applications, each contributing to the market's expansion.

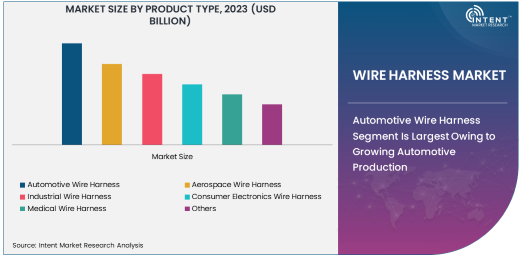

Automotive Wire Harness Segment Is Largest Owing to Growing Automotive Production

Among the product types, the automotive wire harness segment holds the largest market share, driven by the continuous rise in vehicle production and the increasing complexity of automotive electrical systems. With the integration of more electronic components in vehicles—ranging from infotainment systems to advanced driver-assistance systems (ADAS)—automotive wire harnesses have become essential for vehicle manufacturing. These harnesses are integral to the functioning of electrical systems in both internal combustion engine (ICE) vehicles and electric vehicles (EVs), as well as hybrid models.

As the automotive industry moves toward electric vehicles and autonomous driving, there is a growing demand for more sophisticated and durable wire harness solutions. The shift toward EVs, in particular, has led to the adoption of wire harnesses with higher power requirements and improved functionality. Additionally, the trend of lightweighting and miniaturization in vehicles is pushing manufacturers to develop smaller, more efficient wire harnesses. The automotive sector’s massive scale and ongoing advancements are key drivers of this subsegment's growth.

Industrial Wire Harness Segment Is Fastest Growing Due to Increased Industrial Automation

The industrial wire harness segment is the fastest-growing segment, fueled by the increasing demand for automation and industrial machinery in sectors such as manufacturing, oil & gas, and energy. As industries modernize and embrace automation, wire harnesses are crucial for ensuring efficient electrical connections and signaling in complex machinery and equipment. Industrial wire harnesses must endure harsh environments and offer reliable performance under extreme conditions, such as high temperatures, vibrations, and exposure to chemicals.

The rise in Industry 4.0, with its emphasis on automation, robotics, and data exchange, has accelerated the demand for wire harnesses in industrial applications. These harnesses are now being used in a wide range of applications, from factory equipment to robotics and smart manufacturing systems. Additionally, the need for industrial wire harnesses in renewable energy sectors, such as wind and solar power generation, further contributes to this segment's rapid expansion.

Copper Material Type Is Largest Owing to High Conductivity and Reliability

Copper remains the largest material type in the wire harness market due to its excellent electrical conductivity, reliability, and cost-effectiveness. Copper wire harnesses are widely used in automotive, industrial, and consumer electronics applications because of their high performance and low resistance, ensuring optimal electrical signal transmission. The global demand for copper is steadily increasing, driven by the growing reliance on electrical systems in virtually every industry.

Copper-based wire harnesses are particularly prominent in the automotive sector, where the need for high-performance systems and energy-efficient solutions continues to rise. In addition to their use in traditional wire harnesses, copper wires are also being incorporated into the production of electric vehicle charging infrastructure, which further boosts their demand. As industries look to integrate more complex electronic systems, copper continues to be a preferred material due to its proven performance, stability, and wide availability.

Automotive Application Is Largest Due to Rising Demand for Vehicle Electronics

The automotive application segment holds the largest market share in the wire harness market, as vehicles are increasingly equipped with a variety of electronic systems. From advanced safety features, infotainment systems, and lighting to electric powertrains in EVs, wire harnesses are essential for transmitting power and signals across all electrical components in a vehicle. With a significant rise in the adoption of electric vehicles and connected car technologies, the automotive sector is driving the demand for sophisticated wire harness solutions.

As vehicles become more advanced and feature-rich, the need for complex, lightweight, and efficient wire harnesses grows. Automotive manufacturers are also focusing on reducing the overall weight of vehicles, which is leading to the development of more compact wire harnesses. Furthermore, the automotive industry's push toward electrification and smart technology is anticipated to keep driving the demand for wire harnesses in the coming years, making this the largest application segment in the wire harness market.

Asia-Pacific Region Is Fastest Growing Owing to Expanding Manufacturing Base

The Asia-Pacific region is the fastest-growing market for wire harnesses, primarily due to the rapid expansion of manufacturing sectors in countries like China, India, Japan, and South Korea. The region is a global leader in automotive production, electronics manufacturing, and industrial machinery, which significantly contributes to the growing demand for wire harnesses. With increasing investments in electric vehicle production and industrial automation, the region is seeing robust growth in the wire harness market.

China, as the largest manufacturing hub in the world, plays a pivotal role in the region's growth. The country's push toward electrification and smart manufacturing is expected to further fuel the demand for wire harnesses. Additionally, the rise of the Asia-Pacific's telecommunications and consumer electronics sectors further bolsters the market's expansion, making it the fastest-growing region globally.

Competitive Landscape and Leading Companies

The wire harness market is highly competitive, with several key players leading the charge in terms of innovation, production capacity, and market share. Companies like Leoni AG, Yazaki Corporation, Sumitomo Electric Industries, and Motherson Sumi Systems dominate the market with their wide range of wire harness solutions, particularly for the automotive and industrial sectors. These companies are continuously innovating and expanding their product portfolios to meet the demands of industries such as automotive, aerospace, and consumer electronics.

To maintain their competitive edge, leading companies are increasingly focusing on developing high-performance wire harnesses for electric vehicles, renewable energy sectors, and advanced manufacturing systems. Additionally, mergers and acquisitions (M&A) activities are prevalent in the market, with companies looking to expand their geographic footprint and diversify their offerings. As the wire harness market evolves, these companies are expected to continue driving growth through technological advancements, strategic partnerships, and robust production capabilities

List of Leading Companies:

- Leoni AG

- Yazaki Corporation

- Sumitomo Electric Industries

- Denso Corporation

- Motherson Sumi Systems

- Lear Corporation

- Aptiv PLC

- Furukawa Electric Co., Ltd.

- Kostal Group

- TE Connectivity

- Delphi Technologies

- SABIC

- Amphenol Corporation

- Samvardhana Motherson International Ltd.

- Illinois Tool Works (ITW)

Recent Developments:

- Yazaki Corporation announced the opening of a new production facility in Mexico to cater to the growing demand for automotive wire harnesses.

- Leoni AG unveiled new, environmentally friendly wire harness systems designed to reduce vehicle weight and improve energy efficiency in electric cars.

- Aptiv PLC entered into a strategic partnership with a leading automotive manufacturer to provide advanced wiring solutions for next-generation electric vehicles.

- Lear Corporation completed the acquisition of a wire harness production facility in Eastern Europe to enhance its automotive offerings in the region.

- Sumitomo Electric Industries launched a new line of automotive wire harnesses incorporating AI-driven technology for improved assembly and quality control.

Report Scope:

|

Report Features |

Description |

|

Market Size (2023) |

USD 81.4 Billion |

|

Forecasted Value (2030) |

USD 134.2 Billion |

|

CAGR (2024 – 2030) |

7.4% |

|

Base Year for Estimation |

2023 |

|

Historic Year |

2022 |

|

Forecast Period |

2024 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Wire Harness Market By Product Type (Automotive Wire Harness, Aerospace Wire Harness, Industrial Wire Harness, Consumer Electronics Wire Harness, Medical Wire Harness), By End-User Industry (Automotive, Aerospace & Defense, Industrial Manufacturing, Telecommunications, Consumer Electronics, Medical Devices), By Material Type (Copper, Aluminum, Hybrid Materials), By Application (Automotive, Aerospace & Defense, Consumer Electronics, Telecommunications, Medical Devices, Industrial Equipment) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Leoni AG, Yazaki Corporation, Sumitomo Electric Industries, Denso Corporation, Motherson Sumi Systems, Lear Corporation, Aptiv PLC, Furukawa Electric Co., Ltd., Kostal Group, TE Connectivity, Delphi Technologies, SABIC, Amphenol Corporation, Samvardhana Motherson International Ltd., Illinois Tool Works (ITW) |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Wire Harness Market, by Product Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Automotive Wire Harness |

|

4.2. Aerospace Wire Harness |

|

4.3. Industrial Wire Harness |

|

4.4. Consumer Electronics Wire Harness |

|

4.5. Medical Wire Harness |

|

4.6. Others |

|

5. Wire Harness Market, by End-User Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Automotive |

|

5.2. Aerospace & Defense |

|

5.3. Industrial Manufacturing |

|

5.4. Telecommunications |

|

5.5. Consumer Electronics |

|

5.6. Medical Devices |

|

5.7. Others |

|

6. Wire Harness Market, by Material Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Copper |

|

6.2. Aluminum |

|

6.3. Hybrid Materials |

|

6.4. Others |

|

7. Wire Harness Market, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Automotive |

|

7.2. Aerospace & Defense |

|

7.3. Consumer Electronics |

|

7.4. Telecommunications |

|

7.5. Medical Devices |

|

7.6. Industrial Equipment |

|

7.7. Others |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Wire Harness Market, by Product Type |

|

8.2.7. North America Wire Harness Market, by End-User Industry |

|

8.2.8. North America Wire Harness Market, by Material Type |

|

8.2.9. North America Wire Harness Market, by Application |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Wire Harness Market, by Product Type |

|

8.2.10.1.2. US Wire Harness Market, by End-User Industry |

|

8.2.10.1.3. US Wire Harness Market, by Material Type |

|

8.2.10.1.4. US Wire Harness Market, by Application |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. Leoni AG |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. Yazaki Corporation |

|

10.3. Sumitomo Electric Industries |

|

10.4. Denso Corporation |

|

10.5. Motherson Sumi Systems |

|

10.6. Lear Corporation |

|

10.7. Aptiv PLC |

|

10.8. Furukawa Electric Co., Ltd. |

|

10.9. Kostal Group |

|

10.10. TE Connectivity |

|

10.11. Delphi Technologies |

|

10.12. SABIC |

|

10.13. Amphenol Corporation |

|

10.14. Samvardhana Motherson International Ltd. |

|

10.15. Illinois Tool Works (ITW) |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Wire Harness Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Wire Harness Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Wire Harness Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA