As per Intent Market Research, the Vacuum Pumps Market was valued at USD 6.8 billion in 2024-e and will surpass USD 11.2 billion by 2030; growing at a CAGR of 7.3% during 2025 - 2030.

The vacuum pumps market has witnessed steady growth, driven by its diverse applications across industries such as industrial manufacturing, pharmaceuticals, electronics, and food processing. Vacuum pumps play a crucial role in creating low-pressure environments for numerous processes, from material handling to precise manufacturing. As industries focus on improving energy efficiency and automation, the demand for advanced vacuum pump solutions continues to rise. The market is influenced by technological advancements that enhance efficiency and reliability, and the increasing need for clean, contamination-free processes in critical industries such as healthcare and semiconductor manufacturing.

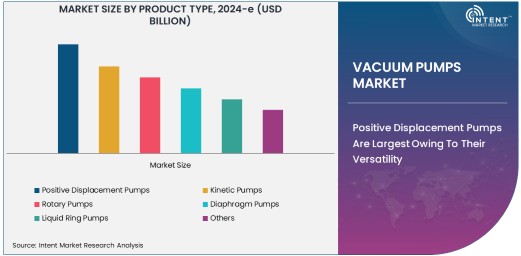

Positive Displacement Pumps Are Largest Owing To Their Versatility

Among the various types of vacuum pumps, positive displacement pumps are the largest segment in the market. These pumps operate by capturing a fixed amount of gas and then forcing it out of the chamber, which makes them ideal for low to medium vacuum applications. They are widely used across industries due to their ability to handle a variety of gases and provide reliable performance in various environments. Positive displacement pumps are often used in critical applications such as chemical processing, food packaging, and pharmaceuticals, where maintaining a specific pressure is essential for quality control.

The versatility of positive displacement pumps also stems from their ability to handle viscous fluids and gases, making them indispensable in the oil and gas and chemical processing industries. As these industries continue to expand and demand higher precision and reliability, the positive displacement pump segment is likely to see sustained growth. The pumps' ability to handle varying flow rates and adapt to different system conditions is a key driver of their dominance in the market.

Dry Vacuum Pumps Are Fastest Growing Owing To Their Clean Operation

Dry vacuum pumps represent the fastest-growing segment within the vacuum pump market, driven by their clean and oil-free operation. These pumps are highly regarded for their ability to maintain a contamination-free environment, making them essential in industries such as pharmaceuticals, food processing, and electronics manufacturing. As industries continue to focus on sustainability and minimizing environmental impact, dry vacuum pumps are increasingly preferred over traditional wet vacuum pumps. Their energy-efficient and low-maintenance design adds to their growing popularity, particularly in the semiconductor and pharmaceutical industries, where cleanliness is paramount.

The healthcare sector is also contributing to the rapid adoption of dry vacuum pumps. These pumps are used in various medical applications, including vacuum-assisted wound therapy and in vacuum chambers for sterilization processes. The demand for clean and efficient technology in the healthcare sector is expected to fuel the growth of dry vacuum pumps, particularly in regions where healthcare infrastructure is expanding.

Industrial Manufacturing Is Largest End-User Industry Owing To Widespread Usage

The industrial manufacturing sector is the largest end-user industry for vacuum pumps, owing to the widespread use of vacuum technology in manufacturing processes. Vacuum pumps are essential in various stages of production, from material handling and filtration to packaging and material processing. Industries such as automotive, food and beverage, and chemicals rely heavily on vacuum pumps to enhance production efficiency and maintain product quality. The need for precise vacuum systems that ensure consistent quality is driving the adoption of vacuum pumps across manufacturing sectors.

As industrial manufacturing continues to grow, especially in emerging economies, the demand for vacuum pumps is expected to remain strong. Manufacturers are increasingly investing in advanced vacuum solutions to meet the requirements of modern production lines, which demand greater efficiency, energy savings, and reduced downtime. The trend of automation and the need for high-performance equipment further solidifies the position of the industrial manufacturing segment as the largest in the vacuum pump market.

Food Processing Is Fastest Growing Application Due To Increased Demand For Packaged Goods

In terms of application, the food processing industry is the fastest-growing sector in the vacuum pump market. The need for vacuum technology in food packaging, preservation, and processing is driving this growth. Vacuum pumps are used extensively in food packaging to extend shelf life by preventing the growth of bacteria and spoilage. With the increasing demand for packaged food and ready-to-eat meals, the food processing sector is heavily relying on vacuum pumps for both product preservation and packaging automation.

Moreover, vacuum pumps are also used in the food processing industry for processes such as vacuum frying and evaporation. These processes help retain the nutritional value and flavor of food, making vacuum pumps a crucial component in modern food manufacturing. As the global population grows and consumer preferences shift toward convenient and healthy food options, the demand for vacuum pumps in the food processing industry is set to increase.

Asia Pacific Is Fastest Growing Region Owing To Rapid Industrialization

The Asia Pacific region is experiencing the fastest growth in the vacuum pumps market. This growth can be attributed to the rapid industrialization in countries like China, India, and Japan, where manufacturing, electronics, and food processing industries are expanding at an unprecedented rate. As these industries grow, the demand for vacuum pumps for applications such as semiconductor production, food packaging, and pharmaceutical manufacturing continues to rise. Additionally, the Asia Pacific region is a hub for global electronics and automotive production, where vacuum pumps play a vital role in maintaining process efficiency and product quality.

The increasing emphasis on automation and energy efficiency in the region further accelerates the adoption of advanced vacuum pumps. Government initiatives to improve industrial infrastructure and the growing focus on sustainability in manufacturing processes are also contributing to the robust demand for vacuum pump solutions in Asia Pacific.

Leading Companies and Competitive Landscape

The vacuum pump market is competitive, with several key players dominating the global landscape. Companies such as Gardner Denver, Atlas Copco, Pfeiffer Vacuum, and EBARA Corporation are leading the market with a diverse portfolio of products designed to meet the varying needs of industrial and commercial applications. These companies have expanded their presence through strategic mergers, acquisitions, and partnerships, enabling them to enhance their product offerings and penetrate emerging markets.

Technological innovation plays a crucial role in the competitive landscape, as manufacturers invest in the development of energy-efficient, low-maintenance, and environmentally friendly vacuum pumps. As industries demand smarter and more efficient vacuum solutions, companies are focusing on integrating IoT capabilities and digital controls into their pumps. This focus on innovation, coupled with strong distribution networks and after-sales service capabilities, positions these leading players at the forefront of the vacuum pump market.

Recent Developments:

- Gardner Denver announced a new range of oil-free vacuum pumps designed to meet the needs of clean industries like pharmaceuticals and food processing.

- Atlas Copco launched a new vacuum pump model with improved energy efficiency and reduced noise levels, aimed at reducing operational costs for industrial users.

- Pfeiffer Vacuum expanded its vacuum pump production facility in Germany to cater to the rising demand for high-performance vacuum solutions in the semiconductor industry.

- Leybold GmbH has entered into a strategic partnership with a leading medical device manufacturer to co-develop vacuum pump solutions for advanced healthcare applications.

- EBARA Corporation completed the acquisition of a European-based company specializing in dry vacuum pumps for the food and beverage industry, strengthening its global footprint.

List of Leading Companies:

- Gardner Denver

- Atlas Copco

- Pfeiffer Vacuum

- Leybold GmbH

- EBARA Corporation

- Busch Vacuum Solutions

- Hibar Systems Ltd.

- ULVAC, Inc.

- KAESER KOMPRESSOREN

- Rough Vacuum Systems

- Shanghai Baolong Vacuum Technology Co., Ltd.

- Dekker Vacuum Technologies, Inc.

- IDEX Corporation

- KNF Neuberger Inc.

- Sumitomo Heavy Industries

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 6.8 Billion |

|

Forecasted Value (2030) |

USD 11.2 Billion |

|

CAGR (2025 – 2030) |

7.3% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Vacuum Pump Market By Product Type (Positive Displacement Pumps, Kinetic Pumps, Rotary Pumps, Diaphragm Pumps, Liquid Ring Pumps), By Technology (Dry Vacuum Pumps, Wet Vacuum Pumps), By End-User Industry (Industrial Manufacturing, Oil & Gas, Semiconductor & Electronics, Chemical & Pharmaceuticals, Food & Beverage, Automotive, Healthcare), and By Application (Food Processing, Chemical Processing, Medical & Pharmaceutical, Packaging, Electronics Manufacturing, Wastewater Treatment) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Gardner Denver, Atlas Copco, Pfeiffer Vacuum, Leybold GmbH, EBARA Corporation, Busch Vacuum Solutions, Hibar Systems Ltd., ULVAC, Inc., KAESER KOMPRESSOREN, Rough Vacuum Systems, Shanghai Baolong Vacuum Technology Co., Ltd., Dekker Vacuum Technologies, Inc., IDEX Corporation, KNF Neuberger Inc., Sumitomo Heavy Industries |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Vacuum Pumps Market, by Product Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Positive Displacement Pumps |

|

4.2. Kinetic Pumps |

|

4.3. Rotary Pumps |

|

4.4. Diaphragm Pumps |

|

4.5. Liquid Ring Pumps |

|

4.6. Others |

|

5. Vacuum Pumps Market, by Technology (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Dry Vacuum Pumps |

|

5.2. Wet Vacuum Pumps |

|

6. Vacuum Pumps Market, by End-User Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Industrial Manufacturing |

|

6.2. Oil & Gas |

|

6.3. Semiconductor & Electronics |

|

6.4. Chemical & Pharmaceuticals |

|

6.5. Food & Beverage |

|

6.6. Automotive |

|

6.7. Healthcare |

|

6.8. Others |

|

7. Vacuum Pumps Market, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Food Processing |

|

7.2. Chemical Processing |

|

7.3. Medical & Pharmaceutical |

|

7.4. Packaging |

|

7.5. Electronics Manufacturing |

|

7.6. Wastewater Treatment |

|

7.7. Others |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Vacuum Pumps Market, by Product Type |

|

8.2.7. North America Vacuum Pumps Market, by Technology |

|

8.2.8. North America Vacuum Pumps Market, by End-User Industry |

|

8.2.9. North America Vacuum Pumps Market, by Application |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Vacuum Pumps Market, by Product Type |

|

8.2.10.1.2. US Vacuum Pumps Market, by Technology |

|

8.2.10.1.3. US Vacuum Pumps Market, by End-User Industry |

|

8.2.10.1.4. US Vacuum Pumps Market, by Application |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. Gardner Denver |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. Atlas Copco |

|

10.3. Pfeiffer Vacuum |

|

10.4. Leybold GmbH |

|

10.5. EBARA Corporation |

|

10.6. Busch Vacuum Solutions |

|

10.7. Hibar Systems Ltd. |

|

10.8. ULVAC, Inc. |

|

10.9. KAESER KOMPRESSOREN |

|

10.10. Rough Vacuum Systems |

|

10.11. Shanghai Baolong Vacuum Technology Co., Ltd. |

|

10.12. Dekker Vacuum Technologies, Inc. |

|

10.13. IDEX Corporation |

|

10.14. KNF Neuberger Inc. |

|

10.15. Sumitomo Heavy Industries |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Vacuum Pump Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Vacuum Pump Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Vacuum Pump Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA