As per Intent Market Research, the Pharmaceutical Isolator market was valued at USD 1.2 Billion in 2024-e and will surpass USD 1.9 Billion by 2030; growing at a CAGR of 8.3% during 2025 - 2030.

The pharmaceutical isolator market is an essential component of the pharmaceutical and biopharmaceutical industries, as it provides a controlled and sterile environment for various manufacturing and research applications. Isolators are designed to create a barrier between sensitive pharmaceutical processes and external contamination, ensuring product integrity and worker safety. With growing concerns regarding contamination control and the need for sterile environments, pharmaceutical isolators play a crucial role in the production of sterile drugs, containment of hazardous substances, and the development of new therapeutic agents. As regulations around drug manufacturing and clinical research become more stringent, the demand for isolators continues to grow, particularly in areas where contamination control is critical.

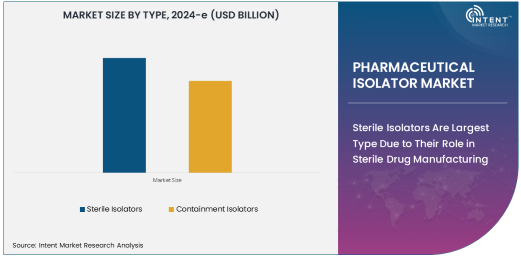

Sterile Isolators Are Largest Type Due to Their Role in Sterile Drug Manufacturing

Sterile isolators represent the largest segment of the pharmaceutical isolator market, driven by their essential role in maintaining sterile conditions during the production of parenteral drugs, biologics, and other critical formulations. These isolators provide a controlled, clean environment that prevents microbial contamination during the manufacturing process. Sterile isolators are crucial for pharmaceutical companies that produce injectable drugs, vaccines, and other sterile products where contamination could result in severe health risks.

The demand for sterile isolators is growing due to the increasing production of sterile drugs and biologics, especially in the fields of oncology, immunology, and vaccines. Furthermore, the heightened awareness of safety and quality standards in drug manufacturing, along with regulatory requirements for aseptic processing, is driving pharmaceutical companies to invest in advanced isolator technology to ensure the sterility of their products.

Containment of Hazardous Drugs Is Fastest Growing Application Due to Safety and Compliance Needs

The containment of hazardous drugs is the fastest growing application in the pharmaceutical isolator market, owing to the increasing need for safety and regulatory compliance in handling cytotoxic and hazardous substances. These drugs, often used in cancer treatments and other critical therapies, can pose significant risks to workers and the environment if not properly contained. Containment isolators provide a safe environment for the handling, compounding, and packaging of hazardous drugs, ensuring that both workers and the surrounding environment remain protected from exposure.

As the use of hazardous drugs increases, particularly in the fields of oncology and specialized therapies, the demand for containment isolators is growing. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) and the USP (United States Pharmacopeia) have implemented stricter guidelines for handling hazardous drugs, further driving the need for containment solutions. Pharmaceutical companies and contract manufacturing organizations (CMOs) are adopting containment isolators to comply with these regulations, ensuring the safety of workers and product integrity.

Pharmaceutical Industry Is Largest End-Use Industry Due to High Demand for Sterile and Hazardous Drug Containment

The pharmaceutical industry is the largest end-use sector for pharmaceutical isolators, driven by the need for sterile manufacturing environments and the handling of hazardous drugs. Pharmaceutical companies require isolators to maintain aseptic conditions during the production of injectable and biologic drugs, as well as to ensure the safe handling of potent drugs. The growing demand for complex biologics, injectables, and oncology treatments has led to an increased reliance on isolators to ensure that products are manufactured under the highest standards of sterility and safety.

Additionally, pharmaceutical companies are expanding their use of isolators to enhance workplace safety and minimize the risk of cross-contamination. This demand is further driven by regulatory requirements and the ongoing push for more efficient, safe, and compliant manufacturing processes. The pharmaceutical industry's emphasis on meeting stringent Good Manufacturing Practices (GMP) and safety standards further strengthens the market for pharmaceutical isolators.

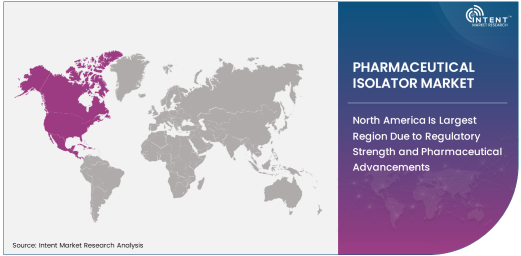

North America Is Largest Region Due to Regulatory Strength and Pharmaceutical Advancements

North America is the largest region in the pharmaceutical isolator market, supported by a robust pharmaceutical industry, stringent regulatory standards, and a strong focus on innovation. The U.S., in particular, is home to numerous pharmaceutical and biopharmaceutical companies, many of which are leading the development and production of sterile drugs and biologics. The regulatory environment in North America, including FDA guidelines and USP regulations, mandates high standards of sterility and safety in drug manufacturing, further boosting the demand for isolators.

North America's advanced healthcare infrastructure, coupled with its investment in cutting-edge technologies, positions the region as a dominant player in the pharmaceutical isolator market. As the pharmaceutical industry continues to innovate and expand, especially in areas such as biologics, oncology drugs, and personalized medicine, the demand for isolators will remain strong in the region.

Competitive Landscape and Key Players

The pharmaceutical isolator market is highly competitive, with key players such as Germfree Laboratories, Siebler, and SKAN AG leading the industry. These companies offer a wide range of isolators, including both sterile and containment types, catering to the needs of pharmaceutical manufacturers, biopharmaceutical companies, and contract manufacturing organizations.

The competitive landscape is marked by continuous innovation in isolator technology, with companies focusing on improving the functionality, safety, and efficiency of their products. Leading players are also investing in automation, remote monitoring, and advanced containment features to enhance the user experience and ensure compliance with ever-evolving regulatory requirements. Strategic partnerships, acquisitions, and collaborations are common in this market as companies look to strengthen their offerings and expand their global presence. The growth of biologics, personalized medicines, and the increasing focus on occupational safety will continue to drive innovation and competition in the pharmaceutical isolator market.

Recent Developments:

- Sartorius AG expanded its portfolio of pharmaceutical isolators to include solutions specifically designed for biologics and cell-based therapies.

- Thermo Fisher Scientific Inc. launched a new range of high-efficiency isolators aimed at increasing production output for pharmaceutical manufacturers.

- Fedegari Autoclavi S.p.A. introduced an upgraded sterile isolator system designed to meet the latest regulatory standards for sterile drug manufacturing.

- Getinge AB secured a significant contract for the supply of pharmaceutical isolators to a leading global biopharmaceutical company.

- Hosokawa Micron Corporation completed a merger with a leading isolator manufacturer to strengthen its product offering in the pharmaceutical market.

List of Leading Companies:

- Sartorius AG

- Getinge AB

- AZO GmbH & Co. KG

- Fedegari Autoclavi S.p.A.

- The Baker Company

- SKAN AG

- IWT (Integrated Work Systems)

- Hosokawa Micron Corporation

- KTL Filtration Ltd.

- Thermo Fisher Scientific Inc.

- VWR International, LLC

- Encapsys LLC

- Tuobio

- Labconco Corporation

- Russell Finex Ltd.

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 1.2 Billion |

|

Forecasted Value (2030) |

USD 1.9 Billion |

|

CAGR (2025 – 2030) |

8.3% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Global Pharmaceutical Isolator Market by Type (Sterile Isolators, Containment Isolators), by Application (Sterile Manufacturing, Containment of Hazardous Drugs, Clinical Drug Research and Development), by End-Use Industry (Pharmaceutical Industry, Biopharmaceuticals, Contract Manufacturing Organizations); Insights & Forecast (2024 – 2030) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Sartorius AG, Getinge AB, AZO GmbH & Co. KG, Fedegari Autoclavi S.p.A., The Baker Company, SKAN AG, Hosokawa Micron Corporation, KTL Filtration Ltd., Thermo Fisher Scientific Inc., VWR International, LLC, Encapsys LLC, Tuobio, Russell Finex Ltd. |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Pharmaceutical Isolator market, by Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Sterile Isolators |

|

4.2. Containment Isolators |

|

5. Pharmaceutical Isolator market, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Sterile Manufacturing |

|

5.2. Containment of Hazardous Drugs |

|

5.3. Clinical Drug Research and Development |

|

6. Pharmaceutical Isolator market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Pharmaceutical Industry |

|

6.2. Biopharmaceuticals |

|

6.3. Contract Manufacturing Organizations |

|

7. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Regional Overview |

|

7.2. North America |

|

7.2.1. Regional Trends & Growth Drivers |

|

7.2.2. Barriers & Challenges |

|

7.2.3. Opportunities |

|

7.2.4. Factor Impact Analysis |

|

7.2.5. Technology Trends |

|

7.2.6. North America Pharmaceutical Isolator market, by Type |

|

7.2.7. North America Pharmaceutical Isolator market, by Application |

|

7.2.8. North America Pharmaceutical Isolator market, by End-Use Industry |

|

7.2.9. By Country |

|

7.2.9.1. US |

|

7.2.9.1.1. US Pharmaceutical Isolator market, by Type |

|

7.2.9.1.2. US Pharmaceutical Isolator market, by Application |

|

7.2.9.1.3. US Pharmaceutical Isolator market, by End-Use Industry |

|

7.2.9.2. Canada |

|

7.2.9.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

7.3. Europe |

|

7.4. Asia-Pacific |

|

7.5. Latin America |

|

7.6. Middle East & Africa |

|

8. Competitive Landscape |

|

8.1. Overview of the Key Players |

|

8.2. Competitive Ecosystem |

|

8.2.1. Level of Fragmentation |

|

8.2.2. Market Consolidation |

|

8.2.3. Product Innovation |

|

8.3. Company Share Analysis |

|

8.4. Company Benchmarking Matrix |

|

8.4.1. Strategic Overview |

|

8.4.2. Product Innovations |

|

8.5. Start-up Ecosystem |

|

8.6. Strategic Competitive Insights/ Customer Imperatives |

|

8.7. ESG Matrix/ Sustainability Matrix |

|

8.8. Manufacturing Network |

|

8.8.1. Locations |

|

8.8.2. Supply Chain and Logistics |

|

8.8.3. Product Flexibility/Customization |

|

8.8.4. Digital Transformation and Connectivity |

|

8.8.5. Environmental and Regulatory Compliance |

|

8.9. Technology Readiness Level Matrix |

|

8.10. Technology Maturity Curve |

|

8.11. Buying Criteria |

|

9. Company Profiles |

|

9.1. Sartorius AG |

|

9.1.1. Company Overview |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

9.2. Getinge AB |

|

9.3. AZO GmbH & Co. KG |

|

9.4. Fedegari Autoclavi S.p.A. |

|

9.5. The Baker Company |

|

9.6. SKAN AG |

|

9.7. IWT (Integrated Work Systems) |

|

9.8. Hosokawa Micron Corporation |

|

9.9. KTL Filtration Ltd. |

|

9.10. Thermo Fisher Scientific Inc. |

|

9.11. VWR International, LLC |

|

9.12. Encapsys LLC |

|

9.13. Tuobio |

|

9.14. Labconco Corporation |

|

9.15. Russell Finex Ltd. |

|

10. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Pharmaceutical Isolator Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Pharmaceutical Isolator Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Pharmaceutical Isolator Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA