As per Intent Market Research, the Metal Recycling Market was valued at USD 56.8 billion and will surpass USD 98.8 billion by 2030; growing at a CAGR of 8.2% during 2024 - 2030.

The Metal Recycling Market is poised for strong growth, driven by increasing awareness of sustainability, rising demand for recycled materials, and the growing emphasis on reducing carbon footprints across industries. As the global population and industrial activities continue to rise, the need for resource-efficient methods of production and waste management is becoming more critical. Metal recycling plays a crucial role in the circular economy by reprocessing scrap metals into usable forms, thereby reducing the demand for raw materials, conserving energy, and decreasing environmental impact. The market is diversified across various types of metals, including steel, aluminum, copper, lead, and precious metals, with each segment serving different industries such as automotive, construction, electronics, and aerospace.

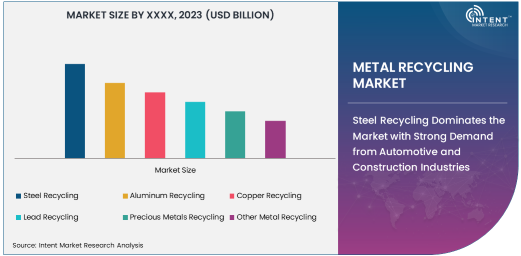

Among the various types of metal recycling, steel recycling emerges as one of the largest subsegments within the market. Steel is one of the most recycled metals globally due to its widespread use in industries such as automotive, construction, and industrial equipment. The high demand for steel in the production of various goods, coupled with its recyclability, makes steel recycling a critical component of the global metal recycling industry. Moreover, recycling steel saves significant amounts of energy, reducing the environmental impact compared to producing steel from raw materials, making it a sustainable choice for manufacturers. As a result, the demand for recycled steel is expected to grow steadily, particularly as governments and organizations increasingly focus on reducing emissions and improving the sustainability of industrial processes.

Steel Recycling Dominates the Market with Strong Demand from Automotive and Construction Industries

The steel recycling subsegment is the largest within the metal recycling market, driven by the widespread use of steel in automotive, construction, and industrial manufacturing sectors. Steel is one of the most recycled materials globally, with its high recyclability and ability to maintain its quality after repeated recycling making it an attractive choice for manufacturers looking to reduce costs and environmental impact. The automotive industry is a significant consumer of recycled steel, with manufacturers using recycled steel to produce a wide range of automotive parts, such as body panels, frames, and engine components. Additionally, the construction industry relies heavily on recycled steel for the construction of buildings, bridges, and other infrastructure, making steel recycling an integral part of the market.

Steel recycling also offers significant environmental benefits, as it reduces the need for mining and processing virgin materials, thereby conserving natural resources and minimizing pollution. The process of recycling steel also requires less energy compared to producing steel from raw materials, resulting in a lower carbon footprint. With increasing pressure from both consumers and governments to adopt more sustainable practices, steel recycling is expected to continue growing, reinforcing its position as the largest subsegment in the market.

Aluminum Recycling Grows Rapidly Due to Demand in Automotive and Packaging

The aluminum recycling segment is one of the fastest-growing subsegments in the metal recycling market, driven by the rising demand for aluminum in industries such as automotive, aerospace, and packaging. Aluminum is a highly recyclable material that retains its properties even after multiple recycling cycles, making it an ideal candidate for use in the production of a wide range of products, from beverage cans to lightweight automotive parts. The automotive industry is a key driver of aluminum recycling, as manufacturers seek to reduce the weight of vehicles to improve fuel efficiency and meet environmental regulations. Recycled aluminum is used to produce automotive components such as wheels, engine parts, and body panels.

In addition to automotive, the packaging industry is another major consumer of recycled aluminum. Aluminum is widely used in the production of beverage cans, food containers, and packaging materials due to its lightweight, durability, and recyclability. The ability to recycle aluminum without losing quality or performance makes it a preferred material in packaging, contributing to the rapid growth of the aluminum recycling segment. As the demand for sustainable packaging solutions and energy-efficient automotive components continues to rise, aluminum recycling is expected to see significant growth in the coming years.

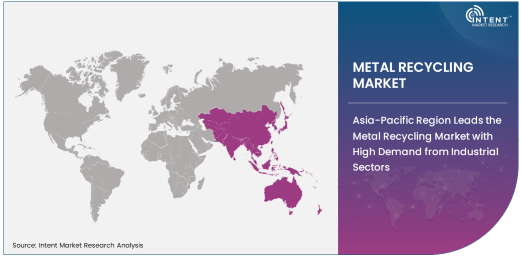

Asia-Pacific Region Leads the Metal Recycling Market with High Demand from Industrial Sectors

The Asia-Pacific (APAC) region holds a dominant position in the metal recycling market, driven by rapid industrialization, increasing urbanization, and the high demand for metals in manufacturing sectors such as automotive, construction, and electronics. Countries like China, India, and Japan are key players in the metal recycling industry due to their large industrial bases and growing focus on sustainable practices. China, in particular, is the world’s largest importer and recycler of scrap metals, fueling demand for recycled metals in industries ranging from automotive to construction.

The APAC region's growing emphasis on recycling and environmental sustainability, coupled with rising demand for recycled metals in key industries, makes it the fastest-growing market for metal recycling. Governments in the region are also implementing stricter regulations to encourage recycling and reduce reliance on virgin materials, further boosting the growth of the market. As industrial activities continue to expand and environmental concerns gain prominence, APAC is expected to remain the leading region in the global metal recycling market.

Leading Companies and Competitive Landscape

The metal recycling market is highly fragmented, with numerous players competing for market share. Leading companies in the market include Sims Metal Management, ArcelorMittal, Nucor Corporation, and Republic Services. These companies are focused on expanding their recycling capacities, adopting advanced technologies, and increasing their presence in emerging markets to meet the growing demand for recycled metals. Innovations in recycling processes, such as chemical recycling and energy recovery, are expected to further enhance the efficiency and sustainability of metal recycling operations.

The competitive landscape is also influenced by strategic partnerships, mergers, and acquisitions, as companies seek to expand their product portfolios and geographic reach. As the demand for recycled metals continues to rise, companies are investing in research and development to improve recycling technologies and reduce operational costs. The increasing emphasis on sustainability and resource efficiency will continue to shape the dynamics of the market, with leading players striving to position themselves as industry leaders in the growing field of metal recycling.

Recent Developments:

- ArcelorMittal announced the launch of a new recycling initiative that aims to increase its scrap metal usage by 20% over the next five years.

- Sims Metal Management expanded its operations with a new state-of-the-art recycling facility in North America to handle increasing demand for recycled metals.

- Tata Steel Limited acquired a leading European metal recycling company to strengthen its position in the secondary raw materials market.

- Novelis Inc. announced a new partnership with automotive manufacturers to increase the use of recycled aluminum in vehicle production.

- U.S. Steel Corporation introduced advanced recycling technologies that reduce the environmental impact of steel production by using more recycled steel in its processes.

List of Leading Companies:

- ArcelorMittal

- Sims Metal Management

- Steel Dynamics, Inc.

- Nucor Corporation

- Tata Steel Limited

- Schnitzer Steel Industries, Inc.

- Commercial Metals Company

- European Metal Recycling (EMR)

- U.S. Steel Corporation

- Novelis Inc.

- Recylex S.A.

- Veolia Environmental Services

- Kuusakoski Group

- Liberty Steel Group

- DOWA Holdings Co., Ltd.

Report Scope:

|

Report Features |

Description |

|

Market Size (2023) |

USD 56.8 billion |

|

Forecasted Value (2030) |

USD 98.8 billion |

|

CAGR (2024 – 2030) |

8.2% |

|

Base Year for Estimation |

2023 |

|

Historic Year |

2022 |

|

Forecast Period |

2024 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Metal Recycling Market By Type (Steel Recycling, Aluminum Recycling, Copper Recycling, Lead Recycling, Precious Metals Recycling), By Process (Mechanical Recycling, Chemical Recycling, Energy Recovery), By Application (Automotive, Construction, Electronics, Packaging, Industrial Equipment, Consumer Goods), By End-Use Industry (Automotive, Construction, Electronics, Aerospace, Energy) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

ArcelorMittal, Sims Metal Management, Steel Dynamics, Inc., Nucor Corporation, Tata Steel Limited, Schnitzer Steel Industries, Inc., Commercial Metals Company, European Metal Recycling (EMR), U.S. Steel Corporation, Novelis Inc., Recylex S.A., Veolia Environmental Services, Kuusakoski Group, Liberty Steel Group, DOWA Holdings Co., Ltd. |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Metal Recycling Market, by Type (Market Size & Forecast: USD Million, 2022 – 2030) |

|

4.1. Steel Recycling |

|

4.2. Aluminum Recycling |

|

4.3. Copper Recycling |

|

4.4. Lead Recycling |

|

4.5. Precious Metals Recycling |

|

4.6. Other Metal Recycling |

|

5. Metal Recycling Market, by Process (Market Size & Forecast: USD Million, 2022 – 2030) |

|

5.1. Mechanical Recycling |

|

5.2. Chemical Recycling |

|

5.3. Energy Recovery |

|

6. Metal Recycling Market, by Application (Market Size & Forecast: USD Million, 2022 – 2030) |

|

6.1. Automotive |

|

6.2. Construction |

|

6.3. Electronics |

|

6.4. Packaging |

|

6.5. Industrial Equipment |

|

6.6. Consumer Goods |

|

7. Metal Recycling Market, by End-Use Industry (Market Size & Forecast: USD Million, 2022 – 2030) |

|

7.1. Automotive |

|

7.2. Construction |

|

7.3. Electronics |

|

7.4. Aerospace |

|

7.5. Energy |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2022 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Metal Recycling Market, by Type |

|

8.2.7. North America Metal Recycling Market, by Process |

|

8.2.8. North America Metal Recycling Market, by Application |

|

8.2.9. North America Metal Recycling Market, by End-Use Industry |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Metal Recycling Market, by Type |

|

8.2.10.1.2. US Metal Recycling Market, by Process |

|

8.2.10.1.3. US Metal Recycling Market, by Application |

|

8.2.10.1.4. US Metal Recycling Market, by End-Use Industry |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. ArcelorMittal |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. Sims Metal Management |

|

10.3. Steel Dynamics, Inc. |

|

10.4. Nucor Corporation |

|

10.5. Tata Steel Limited |

|

10.6. Schnitzer Steel Industries, Inc. |

|

10.7. Commercial Metals Company |

|

10.8. European Metal Recycling (EMR) |

|

10.9. U.S. Steel Corporation |

|

10.10. Novelis Inc. |

|

10.11. Recylex S.A. |

|

10.12. Veolia Environmental Services |

|

10.13. Kuusakoski Group |

|

10.14. Liberty Steel Group |

|

10.15. DOWA Holdings Co., Ltd. |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Metal Recycling Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Metal Recycling Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Metal Recycling Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA