As per Intent Market Research, the Industrial Foam Market was valued at USD 41.2 Billion in 2024-e and will surpass USD 64.2 Billion by 2030; growing at a CAGR of 6.5% during 2025-2030.

The industrial foam market has experienced substantial growth due to its versatility and wide-ranging applications across multiple industries, including automotive, construction, packaging, and healthcare. Foam materials are integral to a variety of products, offering benefits such as lightweight structure, insulation, cushioning, and enhanced durability. As industries continue to evolve, the demand for specialized foam solutions that meet the need for energy efficiency, sustainability, and cost-effectiveness is rising. The market encompasses various types of foams, such as flexible, rigid, spray, and memory foams, each catering to specific requirements in different sectors.

The growth of the industrial foam market is being driven by increasing industrial production and infrastructure development, along with rising consumer demand for products that offer comfort, protection, and sustainability. Additionally, advances in foam production technologies, such as improved material formulations and more eco-friendly manufacturing processes, are contributing to the expansion of the market. With a growing emphasis on innovation and customization in foam products, the industry is poised for continued growth across multiple sectors.

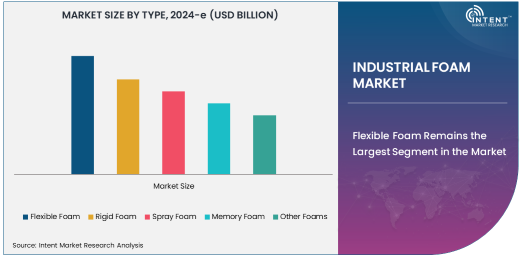

Flexible Foam Remains the Largest Segment in the Market

Flexible foam is the largest segment within the industrial foam market, primarily due to its widespread use across several industries, including automotive, furniture & bedding, and consumer goods. Made from polyurethane, flexible foam is known for its ability to provide comfort, support, and cushioning in various applications. In the automotive industry, flexible foam is used for seating, headrests, and interior padding, contributing to comfort and safety features in vehicles. In the furniture and bedding industries, it plays a significant role in mattresses, cushions, and upholstery, offering superior comfort and durability.

The demand for flexible foam is expected to remain strong as industries continue to prioritize consumer comfort and ergonomic designs. Additionally, with the growing awareness around sustainability, flexible foam manufacturers are focusing on producing more environmentally friendly options, such as bio-based foams and recyclable formulations. This is expected to further boost the adoption of flexible foam across industries, ensuring its position as the largest segment in the industrial foam market.

Polyurethane Foam Leads in Material Use

Polyurethane foam holds the largest share of the material segment in the industrial foam market, thanks to its exceptional versatility, performance, and adaptability across various applications. Polyurethane foam can be formulated to be either flexible or rigid, making it suitable for use in industries such as automotive, construction, and packaging. It is used extensively in automotive interiors for seating and soundproofing, as well as in construction for insulation and weatherproofing. Polyurethane foam is also widely used in the production of mattresses, cushions, and packaging materials, thanks to its ability to provide comfort, protection, and cushioning.

The increasing demand for energy-efficient and sustainable products has driven the development of more eco-friendly polyurethane foams. Innovations such as the use of water-based or bio-based raw materials, as well as advances in recycling and reuse practices, are expanding the appeal of polyurethane foam in various industrial applications. As industries look to balance performance with sustainability, polyurethane foam is expected to remain a dominant material in the industrial foam market.

Automotive Industry Fuels Foam Demand

The automotive industry is the largest end-use sector in the industrial foam market, where foam materials play an essential role in vehicle manufacturing and design. Foams are used extensively in automotive applications, including seating, soundproofing, insulation, and vibration control. Flexible polyurethane foam, in particular, is widely used in the production of car seats, headrests, and armrests, offering comfort, durability, and safety. Additionally, foam insulation materials help in reducing noise, vibration, and harshness (NVH) in vehicles, improving overall ride quality and comfort.

As the automotive industry moves towards electric vehicles (EVs), there is an increasing demand for lightweight materials that help enhance energy efficiency and reduce overall vehicle weight. Foams, particularly polyurethane and memory foams, are ideal solutions for meeting these needs. With the continued development of electric vehicles, the automotive industry's demand for high-performance foams is expected to grow, further solidifying its position as the largest end-use industry in the market.

North America Leads the Industrial Foam Market

North America is currently the largest region in the industrial foam market, driven by high demand in key sectors such as automotive, construction, and healthcare. The region’s advanced industrial infrastructure, strong manufacturing capabilities, and high consumer demand for innovative products have fueled the growth of the foam industry. In particular, the automotive sector in the U.S. has been a major driver of foam adoption, with demand for lightweight and high-performance foams for electric vehicles and traditional automotive applications continuing to rise.

In addition to automotive, the construction industry in North America is experiencing substantial growth, with foam materials being used for insulation, soundproofing, and weatherproofing purposes. As environmental regulations become stricter, the demand for energy-efficient and sustainable foam materials is increasing. Moreover, the healthcare sector in North America continues to drive demand for specialized foams used in medical devices, hospital beds, and patient cushions. As a result, North America is expected to maintain its leading position in the industrial foam market in the coming years.

Competitive Landscape and Key Players

The industrial foam market is highly competitive, with several key players leading the development and innovation of foam products. Notable companies in the market include BASF SE, Covestro AG, Huntsman Corporation, The Dow Chemical Company, and Recticel SA. These players are focusing on expanding their product portfolios, investing in sustainable foam technologies, and exploring new applications to cater to evolving customer demands.

To maintain a competitive edge, companies are increasingly emphasizing research and development to produce high-performance and eco-friendly foams that meet the stringent requirements of industries like automotive, construction, and healthcare. Collaborations, mergers, and acquisitions are common strategies used by key players to enhance their market presence and product offerings. With rising demand for sustainable and advanced foam products, the competitive landscape is expected to remain dynamic, with continuous innovation and strategic alliances shaping the market's future growth trajectory.

Recent Developments:

- BASF SE launched a new series of high-performance polyurethane foams for automotive applications, aimed at improving vehicle insulation and comfort.

- The Dow Chemical Company introduced a new line of spray foam products for use in commercial and residential construction to enhance energy efficiency.

- Huntsman Corporation expanded its production of rigid foams for the packaging industry, targeting sustainability through eco-friendly materials.

- Carpenter Co. unveiled a new foam for bedding products, focused on providing improved durability and comfort for consumers.

- Covestro AG introduced a new polycarbonate-based foam for the electronics industry, offering enhanced thermal and acoustic properties for sensitive components.

List of Leading Companies:

- BASF SE

- The Dow Chemical Company

- Huntsman Corporation

- Covestro AG

- Carpenter Co.

- Armacell International S.A.

- Sekisui Chemical Co. Ltd.

- Rogers Corporation

- Urethane Foam Products, Inc.

- Saint-Gobain Performance Plastics

- Recticel S.A.

- FXI Foamex Innovations, Inc.

- Wacker Chemie AG

- Inoac Corporation

- Flexible Foam Products, Inc.

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 41.2 Billion |

|

Forecasted Value (2030) |

USD 64.2 Billion |

|

CAGR (2025 – 2030) |

6.5% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Industrial Foam Market By Type (Flexible Foam, Rigid Foam, Spray Foam, Memory Foam), By End-Use Industry (Automotive, Construction, Furniture & Bedding, Packaging, Electronics, Healthcare, Consumer Goods), By Material (Polyurethane, Polystyrene, PVC, PET) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

BASF SE, The Dow Chemical Company, Huntsman Corporation, Covestro AG, Carpenter Co., Armacell International S.A., Sekisui Chemical Co. Ltd., Rogers Corporation, Urethane Foam Products, Inc., Saint-Gobain Performance Plastics, Recticel S.A., FXI Foamex Innovations, Inc., Wacker Chemie AG, Inoac Corporation, Flexible Foam Products, Inc. |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Industrial Foam Market, by Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Flexible Foam |

|

4.2. Rigid Foam |

|

4.3. Spray Foam |

|

4.4. Memory Foam |

|

4.5. Other Foams |

|

5. Industrial Foam Market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Automotive |

|

5.2. Construction |

|

5.3. Furniture & Bedding |

|

5.4. Packaging |

|

5.5. Electronics |

|

5.6. Healthcare |

|

5.7. Consumer Goods |

|

5.8. Others |

|

6. Industrial Foam Market, by Material (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Polyurethane |

|

6.2. Polystyrene |

|

6.3. PVC |

|

6.4. PET |

|

6.5. Other Materials |

|

7. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Regional Overview |

|

7.2. North America |

|

7.2.1. Regional Trends & Growth Drivers |

|

7.2.2. Barriers & Challenges |

|

7.2.3. Opportunities |

|

7.2.4. Factor Impact Analysis |

|

7.2.5. Technology Trends |

|

7.2.6. North America Industrial Foam Market, by Type |

|

7.2.7. North America Industrial Foam Market, by End-Use Industry |

|

7.2.8. North America Industrial Foam Market, by Material |

|

7.2.9. By Country |

|

7.2.9.1. US |

|

7.2.9.1.1. US Industrial Foam Market, by Type |

|

7.2.9.1.2. US Industrial Foam Market, by End-Use Industry |

|

7.2.9.1.3. US Industrial Foam Market, by Material |

|

7.2.9.2. Canada |

|

7.2.9.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

7.3. Europe |

|

7.4. Asia-Pacific |

|

7.5. Latin America |

|

7.6. Middle East & Africa |

|

8. Competitive Landscape |

|

8.1. Overview of the Key Players |

|

8.2. Competitive Ecosystem |

|

8.2.1. Level of Fragmentation |

|

8.2.2. Market Consolidation |

|

8.2.3. Product Innovation |

|

8.3. Company Share Analysis |

|

8.4. Company Benchmarking Matrix |

|

8.4.1. Strategic Overview |

|

8.4.2. Product Innovations |

|

8.5. Start-up Ecosystem |

|

8.6. Strategic Competitive Insights/ Customer Imperatives |

|

8.7. ESG Matrix/ Sustainability Matrix |

|

8.8. Manufacturing Network |

|

8.8.1. Locations |

|

8.8.2. Supply Chain and Logistics |

|

8.8.3. Product Flexibility/Customization |

|

8.8.4. Digital Transformation and Connectivity |

|

8.8.5. Environmental and Regulatory Compliance |

|

8.9. Technology Readiness Level Matrix |

|

8.10. Technology Maturity Curve |

|

8.11. Buying Criteria |

|

9. Company Profiles |

|

9.1. BASF SE |

|

9.1.1. Company Overview |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

9.2. The Dow Chemical Company |

|

9.3. Huntsman Corporation |

|

9.4. Covestro AG |

|

9.5. Carpenter Co. |

|

9.6. Armacell International S.A. |

|

9.7. Sekisui Chemical Co. Ltd. |

|

9.8. Rogers Corporation |

|

9.9. Urethane Foam Products, Inc. |

|

9.10. Saint-Gobain Performance Plastics |

|

9.11. Recticel S.A. |

|

9.12. FXI Foamex Innovations, Inc. |

|

9.13. Wacker Chemie AG |

|

9.14. Inoac Corporation |

|

9.15. Flexible Foam Products, Inc. |

|

10. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Industrial Foam Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Industrial Foam Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Industrial Foam Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA