As per Intent Market Research, the Industrial Automation and Control System Market was valued at USD 194.7 billion in 2024-e and will surpass USD 303.8 billion by 2030; growing at a CAGR of 7.7% during 2024 - 2030.

The industrial automation and control system market has been expanding rapidly due to increasing demand for advanced technologies that enhance operational efficiency, reduce human error, and ensure safety in industrial operations. Automation and control systems, including programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems, are critical in industries such as manufacturing, automotive, energy, and food & beverage. These systems enable real-time monitoring, data acquisition, and control of industrial processes, providing businesses with the ability to optimize production, reduce downtime, and improve overall operational performance.

As industries continue to embrace digital transformation, the integration of technologies like the Industrial Internet of Things (IIoT), artificial intelligence (AI), and cloud-based control systems is pushing the market toward the next generation of automation. The rising focus on smart factories and the shift toward more sustainable, automated manufacturing processes are further accelerating market growth. With the increasing need for efficiency, safety, and cost-effectiveness in industries worldwide, the industrial automation and control systems market is expected to experience significant expansion, driven by technological advancements and the growing adoption of automation solutions.

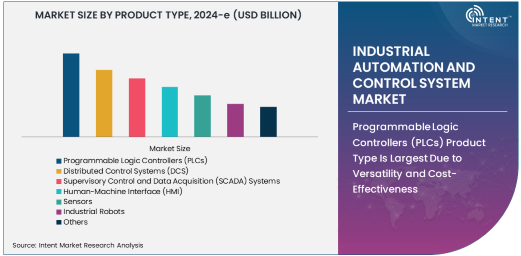

Programmable Logic Controllers (PLCs) Product Type Is Largest Due to Versatility and Cost-Effectiveness

Programmable Logic Controllers (PLCs) are the largest product type in the industrial automation and control system market due to their widespread use and versatility across multiple industries. PLCs are essential in controlling machinery, processes, and assembly lines, and they are widely used in sectors such as manufacturing, automotive, and food & beverage. Their ability to handle complex tasks in real-time, reliability in harsh environments, and ease of integration with other control systems make them indispensable in industrial automation.

The demand for PLCs is driven by their cost-effectiveness and ability to streamline operations by automating repetitive tasks, reducing manual labor, and improving production accuracy. In industries like automotive manufacturing, where precision and efficiency are critical, PLCs are used to control robotic arms, assembly lines, and conveyor systems. As businesses continue to adopt automation to optimize production processes and reduce costs, the need for PLCs will remain high, making it the largest product segment in the market. Additionally, the continuous development of PLCs with enhanced features and increased compatibility with other technologies ensures their continued dominance in the industrial automation and control systems market.

Manufacturing End-Use Industry Is Largest Due to Automation Demand Across Production Lines

The manufacturing industry is the largest end-use sector for industrial automation and control systems, driven by the increasing demand for automation to enhance production efficiency, product quality, and safety. Automation in manufacturing helps optimize production processes, reduce waste, improve precision, and increase overall throughput. PLCs, DCS, SCADA systems, and industrial robots are widely used in manufacturing to automate repetitive tasks, control assembly lines, monitor equipment performance, and ensure high standards of product quality.

The growth of manufacturing in emerging economies, along with advancements in manufacturing technologies, such as Industry 4.0 and smart factories, has further fueled the demand for industrial automation and control systems. Additionally, the push for reducing human errors and improving workplace safety is driving the adoption of automation solutions. As manufacturing industries worldwide continue to embrace automation to stay competitive, the sector will remain the largest end-user of industrial automation and control systems, ensuring sustained market growth.

Industrial Internet of Things (IIoT) Technology Is Fastest Growing Due to Smart Automation Integration

Industrial Internet of Things (IIoT) is the fastest growing technology in the industrial automation and control systems market, owing to the increasing integration of connected devices and systems for real-time data collection, monitoring, and predictive analytics. IIoT connects machines, sensors, and control systems to a central network, enabling businesses to gain real-time insights into operational performance, improve decision-making, and optimize maintenance schedules. The ability to remotely monitor assets, predict failures, and adjust processes based on real-time data has made IIoT a key enabler of smart manufacturing.

The growth of IIoT is driven by the need for greater operational efficiency and sustainability, as well as the rising adoption of cloud-based solutions in industrial environments. IIoT enables the development of predictive maintenance systems, which reduce downtime and extend equipment lifecycles, making it an essential technology for industries like manufacturing, automotive, and energy. As industries continue to embrace smart, data-driven solutions to enhance operational performance, IIoT’s role in industrial automation will continue to expand, making it the fastest growing technology in the market.

Offline Sales Channel Is Largest Due to Established Distribution Networks

The offline sales channel is the largest in the industrial automation and control systems market, primarily due to the well-established distribution networks and long-standing relationships between manufacturers, suppliers, and end-users. Industries such as manufacturing, automotive, and pharmaceuticals often rely on direct sales, local distributors, and specialized vendors to purchase automation systems and equipment. These offline channels offer personalized services, including consultations, installation support, and ongoing maintenance, which are crucial for industries requiring complex, customized solutions.

The reliance on offline sales is particularly strong in industries like manufacturing and oil & gas, where specialized equipment, including PLCs, DCS, and industrial robots, is often sold through dedicated industrial suppliers or systems integrators. Despite the growth of e-commerce, the complexity and high value of industrial automation systems mean that offline channels remain the dominant sales method. As industries demand more tailored solutions and hands-on support, offline sales channels will continue to be the largest segment in the market.

North America Region Is Largest Due to Advanced Industrial Base and Technology Adoption

North America is the largest region in the industrial automation and control systems market, owing to its advanced industrial base, high adoption of technology, and the presence of major market players. The United States, in particular, leads the way in automation adoption, with industries such as manufacturing, automotive, and energy investing heavily in automation solutions to improve efficiency and maintain a competitive edge. North America’s strong focus on innovation and technological advancements, along with government initiatives supporting smart manufacturing and Industry 4.0, has made the region a key market for industrial automation systems.

The region’s manufacturing sector, particularly in automotive and aerospace, remains a significant driver of demand for automation and control systems. Moreover, industries like healthcare, food & beverage, and energy & utilities are also increasingly adopting automation technologies to improve operational efficiency, reduce downtime, and ensure safety. As automation technologies continue to evolve and North American industries embrace more advanced and interconnected systems, the region will continue to dominate the industrial automation and control systems market.

Leading Companies and Competitive Landscape

The industrial automation and control systems market is highly competitive, with several global players shaping its development. Key companies include Siemens AG, Rockwell Automation, ABB Ltd., Schneider Electric, Mitsubishi Electric, and Honeywell International. These companies provide a wide range of automation solutions, including PLCs, DCS, SCADA systems, sensors, and industrial robots, catering to industries like manufacturing, automotive, and energy. Competitive strategies include product innovation, technological advancements, and mergers and acquisitions, as companies aim to expand their portfolios and gain a larger market share.

In recent years, the market has seen a surge in the adoption of IIoT, artificial intelligence, and machine learning, prompting companies to integrate these technologies into their automation solutions. As demand for smarter, more connected systems grows, leading companies are investing heavily in research and development to offer cutting-edge solutions. Additionally, the shift toward cloud-based solutions and decentralized control systems is altering the competitive dynamics, with companies focusing on offering flexible, scalable automation solutions to meet the diverse needs of industries. The ongoing expansion of digitalization and smart manufacturing will continue to shape the competitive landscape of the industrial automation and control systems market.

Recent Developments:

- Siemens AG unveiled a new automation platform designed to enhance the integration of AI and IoT in industrial processes, aimed at improving factory efficiency.

- Rockwell Automation, Inc. acquired a leading control systems company to expand its product portfolio and strengthen its presence in the automation market.

- Schneider Electric SE launched a cloud-based control system for industrial facilities to improve energy management and operational performance.

- Emerson Electric Co. introduced a new suite of industrial control solutions featuring enhanced data analytics and automation features for the energy sector.

- Honeywell International Inc. announced a new partnership to develop advanced AI-driven automation solutions for the manufacturing and automotive sectors.

List of Leading Companies:

- Siemens AG

- ABB Ltd.

- Schneider Electric SE

- Rockwell Automation, Inc.

- Mitsubishi Electric Corporation

- Honeywell International Inc.

- Emerson Electric Co.

- Yokogawa Electric Corporation

- General Electric Company

- Panasonic Corporation

- Omron Corporation

- Fanuc Corporation

- National Instruments Corporation

- KUKA AG

- Invensys Systems Inc.

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 194.7 billion |

|

Forecasted Value (2030) |

USD 303.8 billion |

|

CAGR (2025 – 2030) |

7.7% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Industrial Automation and Control System Market By Product Type (Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) Systems, Human-Machine Interface (HMI), Sensors, Industrial Robots), By End-Use Industry (Manufacturing, Automotive, Energy & Utilities, Oil & Gas, Chemical Processing, Pharmaceuticals, Food & Beverage, Mining), By Technology (Embedded Control Systems, Distributed Control Systems, Cloud-Based Control Systems, Industrial Internet of Things (IIoT), Artificial Intelligence & Machine Learning), By Sales Channel (Online, Offline) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Siemens AG, ABB Ltd., Schneider Electric SE, Rockwell Automation, Inc., Mitsubishi Electric Corporation, Honeywell International Inc., Emerson Electric Co., Yokogawa Electric Corporation, General Electric Company, Panasonic Corporation, Omron Corporation, Fanuc Corporation, National Instruments Corporation, KUKA AG, Invensys Systems Inc. |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Industrial Automation and Control System Market, by Product Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Programmable Logic Controllers (PLCs) |

|

4.2. Distributed Control Systems (DCS) |

|

4.3. Supervisory Control and Data Acquisition (SCADA) Systems |

|

4.4. Human-Machine Interface (HMI) |

|

4.5. Sensors |

|

4.6. Industrial Robots |

|

4.7. Others |

|

5. Industrial Automation and Control System Market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Manufacturing |

|

5.2. Automotive |

|

5.3. Energy & Utilities |

|

5.4. Oil & Gas |

|

5.5. Chemical Processing |

|

5.6. Pharmaceuticals |

|

5.7. Food & Beverage |

|

5.8. Mining |

|

5.9. Others |

|

6. Industrial Automation and Control System Market, by Technology (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Embedded Control Systems |

|

6.2. Distributed Control Systems |

|

6.3. Cloud-Based Control Systems |

|

6.4. Industrial Internet of Things (IIoT) |

|

6.5. Artificial Intelligence & Machine Learning |

|

6.6. Others |

|

7. Industrial Automation and Control System Market, by Sales Channel (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Online |

|

7.2. Offline |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Industrial Automation and Control System Market, by Product Type |

|

8.2.7. North America Industrial Automation and Control System Market, by End-Use Industry |

|

8.2.8. North America Industrial Automation and Control System Market, by Technology |

|

8.2.9. North America Industrial Automation and Control System Market, by Sales Channel |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Industrial Automation and Control System Market, by Product Type |

|

8.2.10.1.2. US Industrial Automation and Control System Market, by End-Use Industry |

|

8.2.10.1.3. US Industrial Automation and Control System Market, by Technology |

|

8.2.10.1.4. US Industrial Automation and Control System Market, by Sales Channel |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. Siemens AG |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. ABB Ltd. |

|

10.3. Schneider Electric SE |

|

10.4. Rockwell Automation, Inc. |

|

10.5. Mitsubishi Electric Corporation |

|

10.6. Honeywell International Inc. |

|

10.7. Emerson Electric Co. |

|

10.8. Yokogawa Electric Corporation |

|

10.9. General Electric Company |

|

10.10. Panasonic Corporation |

|

10.11. Omron Corporation |

|

10.12. Fanuc Corporation |

|

10.13. National Instruments Corporation |

|

10.14. KUKA AG |

|

10.15. Invensys Systems Inc. |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Industrial and Industrial Automation and Control System Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Industrial and Industrial Automation and Control System Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Industrial and Industrial Automation and Control System Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA