As per Intent Market Research, the Fire Tube Industrial Boiler Market was valued at USD 2.1 billion in 2023 and will surpass USD 3.4 billion by 2030; growing at a CAGR of 6.2% during 2024 - 2030.

The fire tube industrial boiler market is an essential component of global industrial infrastructure, providing reliable and efficient heat generation across various applications. These boilers are widely utilized in industries such as chemicals and petrochemicals, food and beverage, and power generation due to their robust performance and operational efficiency. Increasing energy demands, coupled with advancements in boiler technologies, are driving market growth. Environmental regulations emphasizing cleaner energy solutions further shape the industry's landscape.

This analysis examines the largest and fastest-growing subsegments across key market categories, alongside regional insights and competitive dynamics.

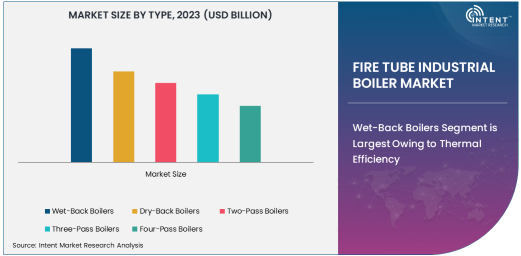

Wet-Back Boilers Segment is Largest Owing to Thermal Efficiency

The wet-back boilers segment dominates the market due to its superior thermal efficiency and reduced maintenance requirements. The water-cooled turnaround chamber in these boilers minimizes heat loss and increases operational reliability, making them a preferred choice in industries that demand consistent performance.

This segment’s dominance is particularly evident in sectors like food and beverage and petrochemicals, where efficient and reliable heat systems are crucial. Additionally, the ability of wet-back boilers to operate with a variety of fuels adds to their versatility, ensuring widespread adoption in industrial applications.

Biomass Fuel Segment is Fastest Growing Owing to Sustainability Trends

The biomass fuel segment is experiencing rapid growth, driven by increasing environmental awareness and a global push towards sustainable energy sources. Biomass-fired boilers offer a renewable and carbon-neutral alternative to traditional fuels, aligning with stringent emissions regulations.

Industries such as pulp and paper and food processing are embracing biomass boilers to reduce their carbon footprints while optimizing energy costs. The availability of advanced combustion technologies further supports the adoption of biomass fuel, propelling its growth in both developed and emerging markets.

10-50 MMBtu/hr Capacity Segment is Largest Owing to Versatile Applications

The 10-50 MMBtu/hr capacity segment holds the largest market share, catering to mid-sized industrial operations requiring efficient heat systems. These boilers offer a balance of capacity and cost-efficiency, making them suitable for a wide range of applications.

Industries like chemicals and petrochemicals, textiles, and power generation favor this capacity range due to its adaptability and reliability. The segment's prominence is bolstered by advancements in boiler designs, enabling enhanced fuel efficiency and compliance with environmental standards.

Food & Beverage End-Use Industry is Fastest Growing Owing to Expanding Operations

The food and beverage industry is emerging as the fastest-growing end-use sector for fire tube industrial boilers. This growth is attributed to rising production demands and the critical role of steam and heat in processes such as sterilization, cooking, and cleaning.

As consumer demand for processed and packaged foods increases, manufacturers are investing in efficient and reliable boiler systems to streamline operations. The industry’s focus on sustainability and energy efficiency further accelerates the adoption of advanced fire tube boilers.

Asia-Pacific Region is Largest Owing to Industrial Expansion

Asia-Pacific leads the fire tube industrial boiler market, driven by rapid industrialization and expanding infrastructure development. Countries like China, India, and Indonesia are key contributors, with strong growth in sectors like chemicals, textiles, and food processing.

Supportive government policies, coupled with increasing energy demands, bolster the adoption of industrial boilers in this region. Additionally, the presence of a robust manufacturing base and investments in cleaner energy technologies strengthen Asia-Pacific’s market position.

Competitive Landscape and Leading Companies

The fire tube industrial boiler market is characterized by intense competition, with major players focusing on innovation, efficiency, and sustainability to gain a competitive edge. Key companies such as Cleaver-Brooks, Bosch Industriekessel, Fulton Boiler Works, and Miura Boilers dominate the market, offering a diverse range of products tailored to industrial needs.

Technological advancements, such as the integration of IoT and automation for real-time performance monitoring, are transforming the competitive landscape. Companies are also investing in cleaner fuel technologies and energy-efficient systems to align with global sustainability goals, ensuring a forward-looking approach in this dynamic market.

Recent Developments:

- Bosch Thermotechnology unveiled a high-efficiency fire tube boiler series with enhanced emission control technologies.

- Cleaver-Brooks introduced a new modular fire tube boiler system aimed at reducing installation costs.

- Thermax Limited announced a major contract to supply fire tube boilers for a large-scale petrochemical complex in Southeast Asia.

- Fulton Boiler Company launched an innovative fire tube boiler for the food and beverage industry, emphasizing compactness and efficiency.

- Hurst Boiler & Welding Co. expanded its manufacturing facility to cater to increasing demand for industrial fire tube boilers in North America.

List of Leading Companies:

- Babcock Wanson

- Bosch Thermotechnology

- Bryan Boilers

- Byworth Boilers

- Cleaver-Brooks

- Cochran Ltd.

- Forbes Marshall

- Fulton Boiler Company

- Hurst Boiler & Welding Co.

- ICI Caldaie S.p.A.

- Johnston Boiler Company

- Miura America Co., Ltd.

- Parker Boiler Company

- Superior Boiler Works, Inc.

- Thermax Limited

Report Scope:

|

Report Features |

Description |

|

Market Size (2023) |

USD 2.1 Billion |

|

Forecasted Value (2030) |

USD 3.4 Billion |

|

CAGR (2024 – 2030) |

6.8% |

|

Base Year for Estimation |

2023 |

|

Historic Year |

2022 |

|

Forecast Period |

2024 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Fire Tube Industrial Boiler Market by Type (Wet-Back Boilers, Dry-Back Boilers, Two-Pass Boilers, Three-Pass Boilers, Four-Pass Boilers), by Fuel Type (Natural Gas, Oil, Coal, Biomass), by Capacity (Up to 10 MMBtu/hr, 10-50 MMBtu/hr, Above 50 MMBtu/hr), by End-Use Industry (Chemicals & Petrochemicals, Food & Beverage, Oil & Gas, Power Generation, Pulp & Paper, Textiles) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Babcock Wanson, Bosch Thermotechnology, Bryan Boilers, Byworth Boilers, Cleaver-Brooks, Cochran Ltd., Fulton Boiler Company, Hurst Boiler & Welding Co., ICI Caldaie S.p.A., Johnston Boiler Company, Miura America Co., Ltd., Parker Boiler Company, Thermax Limited |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Fire Tube Industrial Boiler Market, by Type (Market Size & Forecast: USD Million, 2022 – 2030) |

|

4.1. Wet-Back Boilers |

|

4.2. Dry-Back Boilers |

|

4.3. Two-Pass Boilers |

|

4.4. Three-Pass Boilers |

|

4.5. Four-Pass Boilers |

|

5. Fire Tube Industrial Boiler Market, by Fuel Type (Market Size & Forecast: USD Million, 2022 – 2030) |

|

5.1. Natural Gas |

|

5.2. Oil |

|

5.3. Coal |

|

5.4. Biomass |

|

5.5. Others |

|

6. Fire Tube Industrial Boiler Market, by Capacity (Market Size & Forecast: USD Million, 2022 – 2030) |

|

6.1. Up to 10 MMBtu/hr |

|

6.2. 10-50 MMBtu/hr |

|

6.3. Above 50 MMBtu/hr |

|

7. Fire Tube Industrial Boiler Market, by End-Use Industry (Market Size & Forecast: USD Million, 2022 – 2030) |

|

7.1. Chemicals & Petrochemicals |

|

7.2. Food & Beverage |

|

7.3. Oil & Gas |

|

7.4. Power Generation |

|

7.5. Pulp & Paper |

|

7.6. Textiles |

|

7.7. Others |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2022 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Fire Tube Industrial Boiler Market, by Type |

|

8.2.7. North America Fire Tube Industrial Boiler Market, by Fuel Type |

|

8.2.8. North America Fire Tube Industrial Boiler Market, by Capacity |

|

8.2.9. North America Fire Tube Industrial Boiler Market, by End-Use Industry |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Fire Tube Industrial Boiler Market, by Type |

|

8.2.10.1.2. US Fire Tube Industrial Boiler Market, by Fuel Type |

|

8.2.10.1.3. US Fire Tube Industrial Boiler Market, by Capacity |

|

8.2.10.1.4. US Fire Tube Industrial Boiler Market, by End-Use Industry |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. Babcock Wanson |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. Bosch Thermotechnology |

|

10.3. Bryan Boilers |

|

10.4. Byworth Boilers |

|

10.5. Cleaver-Brooks |

|

10.6. Cochran Ltd. |

|

10.7. Forbes Marshall |

|

10.8. Fulton Boiler Company |

|

10.9. Hurst Boiler & Welding Co. |

|

10.10. ICI Caldaie S.p.A. |

|

10.11. Johnston Boiler Company |

|

10.12. Miura America Co., Ltd. |

|

10.13. Parker Boiler Company |

|

10.14. Superior Boiler Works, Inc. |

|

10.15. Thermax Limited |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Fire Tube Industrial Boiler Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Fire Tube Industrial Boiler Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Fire Tube Industrial Boiler Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA