As per Intent Market Research, the Direct Reduced Iron Market was valued at USD 50.8 billion in 2024-e and will surpass USD 74.6 billion by 2030; growing at a CAGR of 6.6% during 2025 - 2030.

The Direct Reduced Iron (DRI) market is an essential segment of the global iron and steel industry, as it offers a cleaner and more energy-efficient method of producing iron compared to traditional blast furnace processes. DRI production involves the reduction of iron ore using either gas or coal to produce sponge iron, which is then used in electric arc furnaces to create high-quality steel. As industries push toward sustainability, the DRI market is expected to grow rapidly due to its lower carbon footprint and energy efficiency, which align with global green steel initiatives.

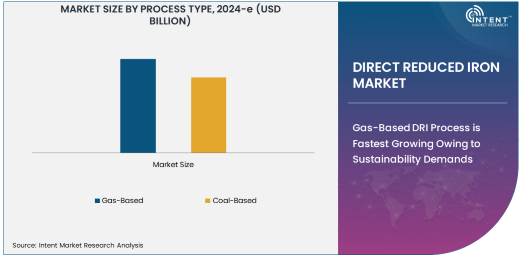

Gas-Based DRI Process is Fastest Growing Owing to Sustainability Demands

The gas-based DRI process is one of the fastest-growing segments in the market, driven primarily by the demand for more sustainable and low-carbon steel production. In this method, natural gas is used as the reducing agent to convert iron ore into sponge iron. This technique is more environmentally friendly than coal-based DRI, as it produces fewer carbon emissions. As steel producers aim to reduce their carbon footprint and align with stringent environmental regulations, the adoption of gas-based DRI technologies has surged. This process is particularly favored in regions with abundant natural gas resources, such as the Middle East, and is a critical component of the green steel movement.

Pellets Segment is Largest Owing to Higher Efficiency and Demand

The pellets segment of the DRI market is the largest due to its superior efficiency in the iron reduction process. Iron ore pellets, which are small, spherical grains made from iron ore, are preferred in DRI plants because they provide a higher quality reduction and are easier to handle compared to lump ore. The uniform size and shape of pellets allow for more efficient heat transfer during the reduction process, leading to improved production yields. As the demand for high-quality steel increases in industries such as automotive and construction, the preference for pellets over other product types continues to grow, cementing its position as the largest subsegment in the DRI market.

Steel Manufacturing Industry is Largest End-Use Industry Owing to Consistent Demand

The steel manufacturing industry remains the largest end-use segment for Direct Reduced Iron due to the high demand for steel in construction, automotive, and infrastructure projects. DRI is a crucial input in steel production, particularly in electric arc furnaces where it can be directly used to produce high-quality steel without the need for additional processing steps. As the global infrastructure development and construction activities continue to rise, particularly in developing economies, the need for steel—and by extension, DRI—remains robust. The demand from steel manufacturers is further bolstered by the industry's shift toward more sustainable practices, which align with the advantages of DRI production methods.

Asia-Pacific Region is Largest Market Owing to High Steel Production

Asia-Pacific is the largest region for the Direct Reduced Iron market, driven by the substantial growth in steel production and consumption across countries like China, India, and Japan. China, the world's largest steel producer, relies heavily on DRI for efficient and sustainable steel production. India's rapidly expanding infrastructure and steel manufacturing industries further fuel the demand for DRI, particularly in the automotive and construction sectors. As the region continues to industrialize, the demand for high-quality steel and, consequently, DRI is expected to remain strong. Additionally, the adoption of gas-based DRI processes in Asia-Pacific is accelerating due to the region’s focus on reducing emissions and enhancing energy efficiency.

Competitive Landscape and Leading Companies

The Direct Reduced Iron market is highly competitive, with several large players dominating the industry. Key companies in this sector include ArcelorMittal, POSCO, Nippon Steel, Tata Steel, and JSW Steel, among others. These companies have invested heavily in expanding their DRI production capabilities, focusing on energy-efficient technologies and sustainable practices to meet the growing demand for green steel. Furthermore, collaborations with technology providers are enabling these companies to adopt more advanced gas-based DRI processes, enhancing their production capacity while reducing carbon emissions. The competitive landscape is also shaped by ongoing investments in the Middle East and Asia-Pacific, where natural gas reserves and government-backed sustainability initiatives provide opportunities for further market expansion.

Recent Developments:

- ArcelorMittal announced the expansion of its DRI production capacity in its European plants, focusing on increasing the production of green steel using hydrogen-based DRI technology.

- POSCO recently unveiled a major investment in its DRI plants in South Korea to improve energy efficiency and reduce carbon emissions as part of its sustainability goals.

- JSW Steel has launched a new project to integrate coal-based DRI production in India, aiming to meet the growing steel demand while reducing production costs.

- Tata Steel has entered into a partnership with a hydrogen-based reduction technology provider to develop an environmentally friendly DRI production facility in Europe.

- Nippon Steel has completed the installation of new DRI production units in Japan, enhancing its ability to meet growing demand for high-quality steel in the automotive sector.

List of Leading Companies:

- ArcelorMittal

- POSCO

- Nippon Steel & Sumitomo Metal Corporation

- Jindal Steel & Power

- Tata Steel

- Hadeed (Saudi Iron and Steel Company)

- JSW Steel

- Thyssenkrupp

- Essar Steel

- Steel Authority of India Limited (SAIL)

- Valin ArcelorMittal Automotive Steel

- Ferrostaal GmbH

- Vallourec

- HBIS Group

- China Baowu Steel Group

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 50.8 Billion |

|

Forecasted Value (2030) |

USD 74.6 Billion |

|

CAGR (2025 – 2030) |

6.6% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Direct Reduced Iron Market By Process Type (Gas-Based, Coal-Based), By Product Type (Pellets, Lump Ore), By End-Use Industry (Steel Manufacturing, Construction, Automotive) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

ArcelorMittal, POSCO, Nippon Steel & Sumitomo Metal Corporation, Jindal Steel & Power, Tata Steel, Hadeed (Saudi Iron and Steel Company), JSW Steel, Thyssenkrupp, Essar Steel, Steel Authority of India Limited (SAIL), Valin ArcelorMittal Automotive Steel, Ferrostaal GmbH, Vallourec, HBIS Group, China Baowu Steel Group |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Direct Reduced Iron Market, by Process Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Gas-Based |

|

4.2. Coal-Based |

|

5. Direct Reduced Iron Market, by Product Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Pellets |

|

5.2. Lump Ore |

|

5.3. Others |

|

6. Direct Reduced Iron Market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Steel Manufacturing |

|

6.2. Construction |

|

6.3. Automotive |

|

6.4. Others |

|

7. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Regional Overview |

|

7.2. North America |

|

7.2.1. Regional Trends & Growth Drivers |

|

7.2.2. Barriers & Challenges |

|

7.2.3. Opportunities |

|

7.2.4. Factor Impact Analysis |

|

7.2.5. Technology Trends |

|

7.2.6. North America Direct Reduced Iron Market, by Process Type |

|

7.2.7. North America Direct Reduced Iron Market, by Product Type |

|

7.2.8. North America Direct Reduced Iron Market, by End-Use Industry |

|

7.2.9. By Country |

|

7.2.9.1. US |

|

7.2.9.1.1. US Direct Reduced Iron Market, by Process Type |

|

7.2.9.1.2. US Direct Reduced Iron Market, by Product Type |

|

7.2.9.1.3. US Direct Reduced Iron Market, by End-Use Industry |

|

7.2.9.2. Canada |

|

7.2.9.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

7.3. Europe |

|

7.4. Asia-Pacific |

|

7.5. Latin America |

|

7.6. Middle East & Africa |

|

8. Competitive Landscape |

|

8.1. Overview of the Key Players |

|

8.2. Competitive Ecosystem |

|

8.2.1. Level of Fragmentation |

|

8.2.2. Market Consolidation |

|

8.2.3. Product Innovation |

|

8.3. Company Share Analysis |

|

8.4. Company Benchmarking Matrix |

|

8.4.1. Strategic Overview |

|

8.4.2. Product Innovations |

|

8.5. Start-up Ecosystem |

|

8.6. Strategic Competitive Insights/ Customer Imperatives |

|

8.7. ESG Matrix/ Sustainability Matrix |

|

8.8. Manufacturing Network |

|

8.8.1. Locations |

|

8.8.2. Supply Chain and Logistics |

|

8.8.3. Product Flexibility/Customization |

|

8.8.4. Digital Transformation and Connectivity |

|

8.8.5. Environmental and Regulatory Compliance |

|

8.9. Technology Readiness Level Matrix |

|

8.10. Technology Maturity Curve |

|

8.11. Buying Criteria |

|

9. Company Profiles |

|

9.1. ArcelorMittal |

|

9.1.1. Company Overview |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

9.2. POSCO |

|

9.3. Nippon Steel & Sumitomo Metal Corporation |

|

9.4. Jindal Steel & Power |

|

9.5. Tata Steel |

|

9.6. Hadeed (Saudi Iron and Steel Company) |

|

9.7. JSW Steel |

|

9.8. Thyssenkrupp |

|

9.9. Essar Steel |

|

9.10. Steel Authority of India Limited (SAIL) |

|

9.11. Valin ArcelorMittal Automotive Steel |

|

9.12. Ferrostaal GmbH |

|

9.13. Vallourec |

|

9.14. HBIS Group |

|

9.15. China Baowu Steel Group |

|

10. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Direct Reduced Iron Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Direct Reduced Iron Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Direct Reduced Iron Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA