As per Intent Market Research, the Bioplastic Composites Market for Injection Molding was valued at USD 2.2 billion in 2023 and will surpass USD 4.0 billion by 2030; growing at a CAGR of 9.1% during 2024 - 2030.

The bioplastic composites market for injection molding is witnessing significant growth, driven by the increasing demand for sustainable and eco-friendly materials across various industries. Bioplastic composites combine bioplastics with natural or synthetic reinforcement materials to enhance mechanical properties, such as strength, durability, and flexibility, while maintaining the environmental benefits of bioplastics. As global concerns over plastic waste and environmental sustainability rise, industries are actively exploring alternative materials that reduce dependence on petroleum-based plastics, and bioplastic composites provide an ideal solution.

The injection molding process, known for its efficiency and ability to produce complex shapes with precision, is widely used in the manufacturing of bioplastic composite products. This technology allows for the mass production of components with consistent quality, making it suitable for applications in industries like automotive, packaging, consumer goods, and electronics. As consumer preferences shift toward environmentally friendly products, the demand for bioplastic composites in injection molding applications is poised to expand significantly, aligning with the growing emphasis on sustainability and reducing the carbon footprint.

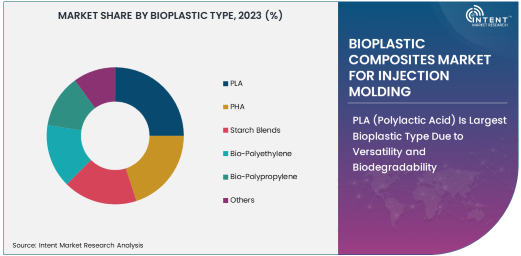

PLA (Polylactic Acid) Is Largest Bioplastic Type Due to Versatility and Biodegradability

PLA (Polylactic Acid) holds the largest share of the bioplastic composites market, owing to its versatility, biodegradability, and ease of processing. PLA is derived from renewable resources like corn starch or sugarcane, making it a popular choice for manufacturers seeking to replace petroleum-based plastics. It is widely used in injection molding for producing a range of products, from packaging materials to automotive components. PLA’s excellent transparency, low toxicity, and ability to be customized for different applications make it an attractive option across various sectors.

In addition to its environmental benefits, PLA offers superior mechanical properties when combined with natural fibers or other reinforcing agents, which enhances its durability and strength. As the demand for biodegradable and recyclable plastics increases, PLA continues to be the preferred choice in bioplastic composite formulations. With the rising trend of sustainability and eco-conscious production practices, the demand for PLA-based bioplastic composites in injection molding applications is expected to grow significantly, making it a dominant player in the market.

Natural Fibers Are Largest Reinforcement Type for Cost-Effectiveness and Sustainability

Natural fibers are the largest reinforcement type used in bioplastic composites for injection molding due to their cost-effectiveness, sustainability, and positive environmental impact. Common natural fibers, such as jute, flax, hemp, and kenaf, are renewable, biodegradable, and contribute to reducing the carbon footprint of composite materials. Natural fibers are increasingly being integrated with bioplastics like PLA and PHA to create eco-friendly composites that offer comparable mechanical properties to traditional plastic composites.

The use of natural fibers in bioplastic composites helps manufacturers reduce the environmental impact of production processes while also benefiting from a lightweight, durable, and functional material. These composites find applications across industries, particularly in automotive components, consumer goods, and packaging, where environmental sustainability is a key driver. As the demand for green materials rises, natural fibers will continue to play a dominant role in bioplastic composite formulations, offering a sustainable alternative to synthetic fibers and promoting eco-friendly manufacturing practices.

Automotive Components Are Largest Application Due to Eco-Friendly Materials Demand

Automotive components are the largest application segment in the bioplastic composites market for injection molding, driven by the automotive industry's increasing focus on sustainability and reducing the environmental impact of production. Bioplastic composites, particularly those reinforced with natural fibers, are widely used in the manufacturing of interior and exterior automotive parts, such as door panels, dashboards, seatbacks, and trim components. These materials offer a lightweight alternative to conventional plastics, helping to reduce vehicle weight and improve fuel efficiency.

The automotive sector’s shift toward adopting environmentally friendly materials is further accelerated by stricter government regulations on emissions and the growing consumer demand for green products. Bioplastic composites, with their strong mechanical properties, biodegradability, and lightweight nature, are an ideal fit for automotive applications. As automakers continue to prioritize sustainability, the demand for bioplastic composites in automotive manufacturing is expected to remain strong, making automotive components the leading application in the market.

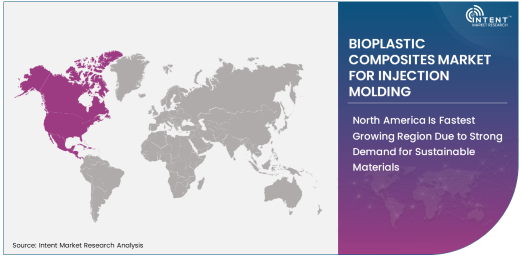

North America Is Fastest Growing Region Due to Strong Demand for Sustainable Materials

North America is the fastest-growing region in the bioplastic composites market for injection molding, driven by the increasing demand for sustainable and eco-friendly materials in various industries. The region has witnessed a significant rise in consumer awareness regarding environmental issues and a growing preference for green products. This has led manufacturers in sectors like automotive, packaging, and consumer goods to seek alternatives to traditional petroleum-based plastics, thus boosting the demand for bioplastic composites.

Government policies and incentives promoting the use of renewable resources, coupled with advancements in bioplastic technology, are further fueling the growth of the market in North America. The region’s well-established manufacturing infrastructure, along with a strong focus on research and development, enables it to remain at the forefront of innovations in bioplastics and composite materials. As North American companies continue to prioritize sustainability in their operations, the demand for bioplastic composites for injection molding is expected to grow at a rapid pace in the coming years.

Competitive Landscape and Leading Companies

The bioplastic composites market for injection molding is highly competitive, with numerous players striving to develop innovative, high-performance products that meet the increasing demand for sustainable materials. Leading companies in the market include BASF SE, UPM-Kymmene Corporation, NatureWorks LLC, and DuPont, among others. These companies are focusing on expanding their product portfolios, advancing bioplastic technologies, and forging strategic partnerships to strengthen their position in the market.

As the demand for bioplastic composites grows, companies are investing in research and development to improve the performance of bioplastic composites and expand their applications. The market is also witnessing an increasing number of collaborations between bioplastic manufacturers and end-user industries, particularly in automotive and packaging, as they seek to meet sustainability goals and reduce the environmental impact of their products. The competitive landscape is expected to continue evolving as the market expands, with innovation and sustainability being key differentiators in the industry.

Recent Developments:

- In December 2024, NatureWorks LLC launched a new range of PLA-based composites for automotive parts, offering improved strength and heat resistance while remaining eco-friendly.

- In November 2024, Dow Chemical Company unveiled a new line of bio-based polypropylene composites designed for consumer goods and packaging applications.

- In October 2024, Braskem announced an expansion in its bioplastic production facilities to meet the growing demand for injection molding applications in the automotive industry.

- In September 2024, BASF SE introduced a new natural fiber-reinforced bioplastic composite for the packaging industry, which is lightweight and fully biodegradable.

- In August 2024, UPM-Kymmene Corporation launched a new bioplastic composite material for electronics, providing sustainable alternatives to conventional plastic components.

List of Leading Companies:

- BASF SE

- Dow Chemical Company

- NatureWorks LLC

- TotalEnergies

- Braskem

- UPM-Kymmene Corporation

- Sabic

- Arkema

- Trex Company, Inc.

- FlexForm Technologies

- Novamont

- Solvay SA

- Mitsubishi Chemical Corporation

- Toray Industries, Inc.

- Sappi Limited

Report Scope:

|

Report Features |

Description |

|

Market Size (2023) |

USD 2.2 billion |

|

Forecasted Value (2030) |

USD 4.0 billion |

|

CAGR (2024 – 2030) |

9.1% |

|

Base Year for Estimation |

2023 |

|

Historic Year |

2022 |

|

Forecast Period |

2024 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Bioplastic Composites Market for Injection Molding By Bioplastic Type (PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), Starch Blends, Bio-Polyethylene, Bio-Polypropylene), By Reinforcement Type (Natural Fibers, Glass Fibers, Carbon Fibers, Mineral Fillers), By Application (Automotive Components, Packaging, Consumer Goods, Electronics) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

BASF SE, Dow Chemical Company, NatureWorks LLC, TotalEnergies, Braskem, UPM-Kymmene Corporation, Sabic, Arkema, Trex Company, Inc., FlexForm Technologies, Novamont, Solvay SA, Mitsubishi Chemical Corporation, Toray Industries, Inc., Sappi Limited |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Bioplastic Composites Market for Injection Molding, by Bioplastic Type (Market Size & Forecast: USD Million, 2022 – 2030) |

|

4.1. PLA (Polylactic Acid) |

|

4.2. PHA (Polyhydroxyalkanoates) |

|

4.3. Starch Blends |

|

4.4. Bio-Polyethylene |

|

4.5. Bio-Polypropylene |

|

4.6. Others |

|

5. Bioplastic Composites Market for Injection Molding, by Reinforcement Type (Market Size & Forecast: USD Million, 2022 – 2030) |

|

5.1. Natural Fibers |

|

5.2. Glass Fibers |

|

5.3. Carbon Fibers |

|

5.4. Mineral Fillers |

|

5.5. Others |

|

6. Bioplastic Composites Market for Injection Molding, by Application (Market Size & Forecast: USD Million, 2022 – 2030) |

|

6.1. Automotive Components |

|

6.2. Packaging |

|

6.3. Consumer Goods |

|

6.4. Electronics |

|

6.5. Others |

|

7. Regional Analysis (Market Size & Forecast: USD Million, 2022 – 2030) |

|

7.1. Regional Overview |

|

7.2. North America |

|

7.2.1. Regional Trends & Growth Drivers |

|

7.2.2. Barriers & Challenges |

|

7.2.3. Opportunities |

|

7.2.4. Factor Impact Analysis |

|

7.2.5. Technology Trends |

|

7.2.6. North America Bioplastic Composites Market for Injection Molding, by Bioplastic Type |

|

7.2.7. North America Bioplastic Composites Market for Injection Molding, by Reinforcement Type |

|

7.2.8. North America Bioplastic Composites Market for Injection Molding, by Application |

|

7.2.9. By Country |

|

7.2.9.1. US |

|

7.2.9.1.1. US Bioplastic Composites Market for Injection Molding, by Bioplastic Type |

|

7.2.9.1.2. US Bioplastic Composites Market for Injection Molding, by Reinforcement Type |

|

7.2.9.1.3. US Bioplastic Composites Market for Injection Molding, by Application |

|

7.2.9.2. Canada |

|

7.2.9.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

7.3. Europe |

|

7.4. Asia-Pacific |

|

7.5. Latin America |

|

7.6. Middle East & Africa |

|

8. Competitive Landscape |

|

8.1. Overview of the Key Players |

|

8.2. Competitive Ecosystem |

|

8.2.1. Level of Fragmentation |

|

8.2.2. Market Consolidation |

|

8.2.3. Product Innovation |

|

8.3. Company Share Analysis |

|

8.4. Company Benchmarking Matrix |

|

8.4.1. Strategic Overview |

|

8.4.2. Product Innovations |

|

8.5. Start-up Ecosystem |

|

8.6. Strategic Competitive Insights/ Customer Imperatives |

|

8.7. ESG Matrix/ Sustainability Matrix |

|

8.8. Manufacturing Network |

|

8.8.1. Locations |

|

8.8.2. Supply Chain and Logistics |

|

8.8.3. Product Flexibility/Customization |

|

8.8.4. Digital Transformation and Connectivity |

|

8.8.5. Environmental and Regulatory Compliance |

|

8.9. Technology Readiness Level Matrix |

|

8.10. Technology Maturity Curve |

|

8.11. Buying Criteria |

|

9. Company Profiles |

|

9.1. BASF SE |

|

9.1.1. Company Overview |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

9.2. Dow Chemical Company |

|

9.3. NatureWorks LLC |

|

9.4. TotalEnergies |

|

9.5. Braskem |

|

9.6. UPM-Kymmene Corporation |

|

9.7. Sabic |

|

9.8. Arkema |

|

9.9. Trex Company, Inc. |

|

9.10. FlexForm Technologies |

|

9.11. Novamont |

|

9.12. Solvay SA |

|

9.13. Mitsubishi Chemical Corporation |

|

9.14. Toray Industries, Inc. |

|

9.15. Sappi Limited |

|

10. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Bioplastic Composites Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Bioplastic Composites Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Bioplastic Composites Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA