As per Intent Market Research, the Automotive Metals Market was valued at USD 165.3 Billion in 2024-e and will surpass USD 214.5 Billion by 2030; growing at a CAGR of 4.4% during 2025-2030.

The automotive metals market is a crucial segment within the global automotive industry, driven by the need for lightweight, durable, and cost-effective materials for manufacturing vehicle components. This market includes a variety of metals, such as steel, aluminum, magnesium, and zinc, used across different vehicle segments like passenger cars, commercial vehicles, and electric vehicles (EVs). The demand for automotive metals is influenced by the push for fuel efficiency, regulatory compliance for emissions, and the increasing production of electric vehicles. These factors make automotive metals an essential part of the supply chain, enabling automotive manufacturers to meet evolving performance and sustainability standards.

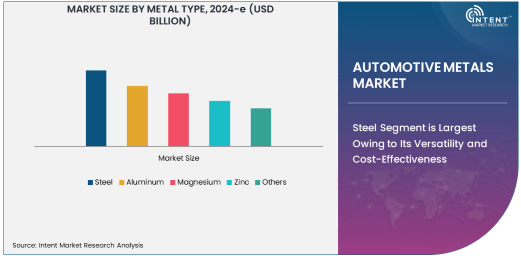

Steel Segment is Largest Owing to Its Versatility and Cost-Effectiveness

Steel is by far the largest segment in the automotive metals market, owing to its versatility, cost-effectiveness, and strength. It is primarily used in various vehicle components such as body panels, chassis, and structural parts. Steel alloys, including high-strength steel (HSS) and advanced high-strength steel (AHSS), provide both strength and lightweight properties, making them ideal for improving fuel efficiency without compromising safety. Additionally, steel’s abundant availability and lower cost compared to other metals make it the preferred choice for mass production of automotive components.

The automotive industry increasingly demands advanced steel grades to meet the rising safety and fuel efficiency standards in vehicles. Innovations in steel technology, such as ultra-high-strength steels and lightweight steel, are further enhancing its appeal. Steel’s role in the production of passenger cars and commercial vehicles, coupled with its application in electric vehicle (EV) manufacturing, underscores its dominant position in the automotive metals market. As a result, steel continues to play a pivotal role in shaping the future of the automotive industry.

Aluminum Segment is Fastest Growing Owing to Lightweighting Demands

Aluminum is experiencing the fastest growth in the automotive metals market, driven by the increasing demand for lightweight materials, particularly in the context of improving fuel efficiency and reducing carbon emissions. Aluminum is widely used in automotive body panels, engine components, and transmission parts due to its lightweight yet strong properties. As automakers focus on reducing vehicle weight to enhance fuel economy and meet stringent emissions regulations, aluminum is becoming an essential material in vehicle manufacturing, particularly for electric vehicles (EVs).

The rise in electric vehicle production is a key driver of the growth of aluminum in the automotive sector. EV manufacturers are increasingly turning to aluminum to offset the weight of batteries and improve overall vehicle performance. This trend is expected to continue as more automakers invest in electric mobility and explore new ways to enhance the energy efficiency of EVs. As aluminum continues to be a preferred material for lightweighting, its share in the automotive metals market is poised to grow significantly.

Passenger Cars Segment is Largest Owing to High Demand and Production Volume

Passenger cars represent the largest segment in the automotive metals market, primarily because of the high production volumes and the continued global demand for personal transportation. The automotive industry is witnessing a steady rise in passenger car production, driven by factors such as urbanization, increasing disposable income, and evolving consumer preferences for fuel-efficient, technologically advanced vehicles. As a result, passenger cars demand the largest share of automotive metals, including steel, aluminum, and magnesium, to manufacture components that enhance vehicle strength, safety, and performance.

In addition, the increasing focus on electric vehicles (EVs) is contributing to the growth of passenger car production. Automakers are shifting their focus to producing EVs to cater to the growing demand for environmentally friendly transportation. This shift further drives the demand for automotive metals, particularly aluminum, which is key to reducing weight and improving energy efficiency in electric passenger vehicles. The passenger car segment is expected to maintain its dominance in the automotive metals market as these trends continue.

OEM Segment is Largest Owing to Large-Scale Manufacturing and Consistent Demand

The OEM (Original Equipment Manufacturer) segment is the largest within the automotive metals market, owing to the large-scale manufacturing of vehicles and the consistent demand for high-quality automotive metals. OEMs require a wide range of metals, including steel, aluminum, and magnesium, to produce various vehicle components such as body panels, engines, and structural parts. The OEM sector benefits from mass production efficiencies and economies of scale, making it the dominant end-use industry in the market.

In addition, OEMs play a crucial role in the development of innovative automotive materials. They are actively working with suppliers to create new metal alloys that meet the evolving requirements of vehicle safety, performance, and sustainability. As a result, the OEM segment is likely to maintain its dominant position in the automotive metals market, with continued innovations driving demand for advanced materials across all types of vehicles.

Asia-Pacific Region is Largest Owing to High Production Volumes

The Asia-Pacific region is the largest market for automotive metals, driven by the high production volumes of vehicles in countries such as China, Japan, and India. Asia-Pacific houses some of the world’s largest automobile manufacturers, including Toyota, Hyundai, and Honda, and is the leading region in terms of automotive production. The region also has a robust supply chain for automotive metals, with major suppliers of steel, aluminum, and other materials located within the region.

In addition, the rapid adoption of electric vehicles (EVs) in countries such as China is further boosting the demand for automotive metals. The increasing shift towards EVs in Asia-Pacific is driving the demand for lightweight materials such as aluminum, magnesium, and advanced alloys. As a result, Asia-Pacific is expected to continue leading the automotive metals market due to its dominant position in vehicle manufacturing and its growing focus on sustainable transportation solutions.

Competitive Landscape and Leading Companies

The competitive landscape of the automotive metals market is characterized by the presence of several global players that are leading in terms of production capacity, technological advancements, and market share. Key players in the market include ArcelorMittal, POSCO, Nippon Steel Corporation, Alcoa Corporation, and Novelis Inc. These companies are investing heavily in research and development to create innovative materials that meet the growing demand for lightweight, fuel-efficient, and environmentally friendly vehicles.

As the automotive industry evolves, companies are increasingly focusing on developing advanced steel and aluminum alloys that can reduce vehicle weight while maintaining strength and safety. Additionally, partnerships with OEMs and the growing production of electric vehicles are driving strategic alliances and technological collaborations. The market is competitive, with companies striving to meet the needs of both traditional automakers and EV manufacturers, positioning themselves to lead in a rapidly changing automotive landscape.

Recent Developments:

- ArcelorMittal announced an investment in a new facility to produce high-strength automotive steel for lightweighting and safety improvements in vehicles.

- Alcoa introduced a new range of aluminum alloys designed specifically for electric vehicle manufacturing, focusing on reducing weight while ensuring durability.

- POSCO plans to expand its automotive steel production capacity in South Korea and China to meet the growing demand from electric vehicle manufacturers.

- Tata Steel entered into strategic partnerships with electric vehicle manufacturers to supply lightweight automotive metals to improve the performance of EVs.

- JFE Steel developed new magnesium alloys for use in automotive body panels, enhancing strength and reducing weight for fuel-efficient vehicles.

List of Leading Companies:

- ArcelorMittal

- Nippon Steel Corporation

- BASF

- Aleris Corporation

- Alcoa Corporation

- Thyssenkrupp AG

- POSCO

- Novelis Inc.

- Rio Tinto Group

- Tata Steel

- U.S. Steel Corporation

- General Motors

- Honda Motor Co., Ltd.

- Hyundai Steel Company

- JFE Steel Corporation

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 165.3 Billion |

|

Forecasted Value (2030) |

USD 214.5 Billion |

|

CAGR (2025 – 2030) |

4.4% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Automotive Metals Market By Metal Type (Steel, Aluminum, Magnesium, Zinc), By Application (Body & Chassis, Powertrain, Suspension, Interior, Exterior), By Vehicle Type (Passenger Cars, Commercial Vehicles, Electric Vehicles, Two-Wheelers), By End-Use Industry (OEM, Aftermarket) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

ArcelorMittal, Nippon Steel Corporation, BASF, Aleris Corporation, Alcoa Corporation, Thyssenkrupp AG, POSCO, Novelis Inc., Rio Tinto Group, Tata Steel, U.S. Steel Corporation, General Motors, Honda Motor Co., Ltd., Hyundai Steel Company, JFE Steel Corporation |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Automotive Metals Market, by Metal Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Steel |

|

4.2. Aluminum |

|

4.3. Magnesium |

|

4.4. Zinc |

|

4.5. Others |

|

5. Automotive Metals Market, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Body & Chassis |

|

5.2. Powertrain |

|

5.3. Suspension |

|

5.4. Interior |

|

5.5. Exterior |

|

5.6. Others |

|

6. Automotive Metals Market, by Vehicle Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Passenger Cars |

|

6.2. Commercial Vehicles |

|

6.3. Electric Vehicles (EVs) |

|

6.4. Two-Wheelers |

|

7. Automotive Metals Market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. OEM (Original Equipment Manufacturers) |

|

7.2. Aftermarket |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Automotive Metals Market, by Metal Type |

|

8.2.7. North America Automotive Metals Market, by Application |

|

8.2.8. North America Automotive Metals Market, by Vehicle Type |

|

8.2.9. North America Automotive Metals Market, by End-Use Industry |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Automotive Metals Market, by Metal Type |

|

8.2.10.1.2. US Automotive Metals Market, by Application |

|

8.2.10.1.3. US Automotive Metals Market, by Vehicle Type |

|

8.2.10.1.4. US Automotive Metals Market, by End-Use Industry |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. ArcelorMittal |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. Nippon Steel Corporation |

|

10.3. BASF |

|

10.4. Aleris Corporation |

|

10.5. Alcoa Corporation |

|

10.6. Thyssenkrupp AG |

|

10.7. POSCO |

|

10.8. Novelis Inc. |

|

10.9. Rio Tinto Group |

|

10.10. Tata Steel |

|

10.11. U.S. Steel Corporation |

|

10.12. General Motors |

|

10.13. Honda Motor Co., Ltd. |

|

10.14. Hyundai Steel Company |

|

10.15. JFE Steel Corporation |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Automotive Metals Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Automotive Metals Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Automotive Metals Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA