As per Intent Market Research, the Aseptic Processing Market was valued at USD 55.7 Billion in 2024-e and will surpass USD 111.2 Billion by 2030; growing at a CAGR of 12.2% during 2025 - 2030.

The aseptic processing market plays a crucial role in the preservation of products by ensuring the absence of microbial contamination during the manufacturing and packaging process. This technology is primarily applied in the pharmaceutical, food & beverages, and biotechnology sectors, offering solutions for the safe production of sterile products. Aseptic processing is essential for maintaining the quality and safety of sensitive products, especially in industries where microbial contamination can have severe consequences, such as pharmaceuticals and biotechnology. As demand for sterilized products grows globally, the aseptic processing market is expected to continue expanding, driven by advancements in sterilization technologies and growing consumer demand for high-quality, contaminant-free products.

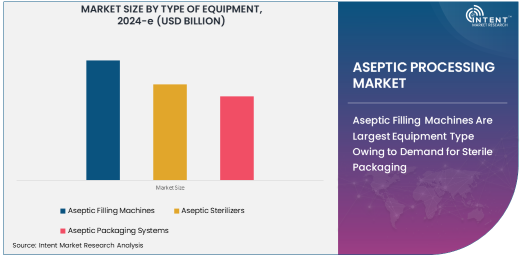

Aseptic Filling Machines Are Largest Equipment Type Owing to Demand for Sterile Packaging

Aseptic filling machines are the largest equipment type in the aseptic processing market due to their integral role in ensuring sterile packaging for a wide variety of products. These machines are designed to fill containers with sterile products without compromising the sterility of the contents, which is crucial for industries like pharmaceuticals and food & beverages. The growing need for packaged beverages, injectable pharmaceuticals, and processed foods that require strict microbial control is pushing the demand for aseptic filling machines.

The flexibility and scalability of aseptic filling machines make them suitable for a wide range of applications, from small-scale batch processing to high-volume, automated production lines. Their importance in maintaining product safety and extending shelf life is a key factor behind their dominance in the market. As industries continue to prioritize hygiene and product integrity, the aseptic filling machine segment will remain a cornerstone of aseptic processing technology.

Pharmaceuticals Is Fastest Growing Application Due to Rising Demand for Sterile Drug Products

The pharmaceuticals application is the fastest growing segment within the aseptic processing market, fueled by increasing demand for sterile drug products and injectable biologics. With the rise in chronic diseases and an aging population, the demand for injectable medications, vaccines, and other sterile pharmaceutical products has surged, driving the adoption of aseptic processing technologies. The critical need for these products to be free of microbial contamination has spurred advancements in aseptic processing, especially in the pharmaceutical industry.

Additionally, the growing focus on biopharmaceuticals and gene therapies, which require sterile manufacturing environments, has further contributed to the rapid growth of this application. As the global pharmaceutical industry expands, particularly in emerging markets, the demand for aseptic processing solutions is expected to grow, making pharmaceuticals the fastest growing application in the market.

Pharmaceutical Manufacturers Are Largest End-Use Industry Owing to High Demand for Aseptic Processing

Pharmaceutical manufacturers are the largest end-use industry in the aseptic processing market, driven by the critical need for sterile environments in drug production. The pharmaceutical industry is one of the primary users of aseptic processing technologies, particularly for the production of injectable drugs, vaccines, and biologics. The importance of maintaining sterility during manufacturing and packaging processes in order to ensure patient safety is a key factor propelling the dominance of pharmaceutical manufacturers in the market.

With increasing regulatory standards and growing global demand for high-quality medicines, pharmaceutical manufacturers rely on aseptic processing equipment to comply with stringent guidelines and to meet market demand. This sector’s constant need for advanced, reliable sterilization and filling technologies ensures the continued dominance of pharmaceutical manufacturers in the aseptic processing market.

North America Is Largest Region Due to Strong Pharmaceutical Manufacturing Sector

North America is the largest region in the aseptic processing market, owing to its robust pharmaceutical manufacturing sector and a high demand for aseptic processing in the food & beverage industry. The U.S., in particular, leads the region in terms of aseptic technology adoption, driven by its advanced healthcare infrastructure, stringent regulatory environment, and high standards for pharmaceutical production. Additionally, North America is home to a significant number of food and beverage manufacturers who rely on aseptic processing to ensure the safety and quality of their products.

With a well-established base for contract manufacturing and leading pharmaceutical companies, North America continues to dominate the aseptic processing market. The region’s focus on research and development in sterile manufacturing processes, coupled with a growing demand for biologics and vaccines, ensures its continued leadership in the market.

Competitive Landscape and Key Players

The aseptic processing market is highly competitive, with several leading companies at the forefront of providing innovative aseptic equipment and solutions. Key players include global giants such as Bosch Packaging Technology, Tetra Pak, and GEA Group, which offer advanced aseptic filling machines, sterilizers, and packaging systems for pharmaceutical and food industries.

As the market continues to grow, there is an increasing trend of collaborations between equipment manufacturers and pharmaceutical companies to develop tailored aseptic processing solutions. Contract manufacturers also play a pivotal role in the market by offering specialized services to the pharmaceutical and food sectors. This competitive landscape is driving continuous innovation in sterilization technologies, with a focus on improving efficiency, reducing costs, and enhancing product safety. Leading players in the market are expected to invest heavily in R&D to maintain a competitive edge, further propelling the growth of the aseptic processing market.

Recent Developments:

- Tetra Pak International S.A. launched an advanced aseptic processing line for dairy products that improves efficiency and reduces energy consumption.

- GEA Group introduced a new aseptic packaging technology designed to extend the shelf life of food products without preservatives.

- Krones AG unveiled its high-speed aseptic filling machine, which enhances production capacity and ensures high product quality in the beverage industry.

- Becton Dickinson and Company (BD) acquired a leading manufacturer of aseptic sterilization equipment, expanding its capabilities in the medical sector.

- Marchesini Group S.p.A. developed a new aseptic filling system that automates processes for small-volume pharmaceutical production, improving reliability and safety.

List of Leading Companies:

- Tetra Pak International S.A.

- GEA Group

- Krones AG

- SPX FLOW, Inc.

- Ishida Co., Ltd.

- Becton Dickinson and Company (BD)

- Seidenader Maschinenbau GmbH

- Robert Bosch GmbH

- Marchesini Group S.p.A.

- KHS GmbH

- Steriline Srl

- Asept Pak

- Graco Inc.

- Syntegon Technology GmbH

- Omron Corporation

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 55.7 Billion |

|

Forecasted Value (2030) |

USD 111.2 Billion |

|

CAGR (2025 – 2030) |

12.2% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Global Aseptic Processing Market by Type of Equipment (Aseptic Filling Machines, Aseptic Sterilizers, Aseptic Packaging Systems), by Application (Pharmaceuticals, Food & Beverages, Biotechnology), by End-Use Industry (Pharmaceutical Manufacturers, Food and Beverage Manufacturers, Contract Manufacturers); Insights & Forecast (2024 – 2030) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Tetra Pak International S.A., GEA Group, Krones AG, SPX FLOW, Inc., Ishida Co., Ltd., Becton Dickinson and Company (BD), Robert Bosch GmbH, Marchesini Group S.p.A., KHS GmbH, Steriline Srl, Asept Pak, Graco Inc., Omron Corporation |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Aseptic Processing Market, by Type of Equipment (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Aseptic Filling Machines |

|

4.2. Aseptic Sterilizers |

|

4.3. Aseptic Packaging Systems |

|

5. Aseptic Processing Market, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Pharmaceuticals |

|

5.2. Food & Beverages |

|

5.3. Biotechnology |

|

6. Aseptic Processing Market, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Pharmaceutical Manufacturers |

|

6.2. Food and Beverage Manufacturers |

|

6.3. Contract Manufacturers |

|

7. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. Regional Overview |

|

7.2. North America |

|

7.2.1. Regional Trends & Growth Drivers |

|

7.2.2. Barriers & Challenges |

|

7.2.3. Opportunities |

|

7.2.4. Factor Impact Analysis |

|

7.2.5. Technology Trends |

|

7.2.6. North America Aseptic Processing Market, by Type of Equipment |

|

7.2.7. North America Aseptic Processing Market, by Application |

|

7.2.8. North America Aseptic Processing Market, by End-Use Industry |

|

7.2.9. By Country |

|

7.2.9.1. US |

|

7.2.9.1.1. US Aseptic Processing Market, by Type of Equipment |

|

7.2.9.1.2. US Aseptic Processing Market, by Application |

|

7.2.9.1.3. US Aseptic Processing Market, by End-Use Industry |

|

7.2.9.2. Canada |

|

7.2.9.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

7.3. Europe |

|

7.4. Asia-Pacific |

|

7.5. Latin America |

|

7.6. Middle East & Africa |

|

8. Competitive Landscape |

|

8.1. Overview of the Key Players |

|

8.2. Competitive Ecosystem |

|

8.2.1. Level of Fragmentation |

|

8.2.2. Market Consolidation |

|

8.2.3. Product Innovation |

|

8.3. Company Share Analysis |

|

8.4. Company Benchmarking Matrix |

|

8.4.1. Strategic Overview |

|

8.4.2. Product Innovations |

|

8.5. Start-up Ecosystem |

|

8.6. Strategic Competitive Insights/ Customer Imperatives |

|

8.7. ESG Matrix/ Sustainability Matrix |

|

8.8. Manufacturing Network |

|

8.8.1. Locations |

|

8.8.2. Supply Chain and Logistics |

|

8.8.3. Product Flexibility/Customization |

|

8.8.4. Digital Transformation and Connectivity |

|

8.8.5. Environmental and Regulatory Compliance |

|

8.9. Technology Readiness Level Matrix |

|

8.10. Technology Maturity Curve |

|

8.11. Buying Criteria |

|

9. Company Profiles |

|

9.1. Tetra Pak International S.A. |

|

9.1.1. Company Overview |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

9.2. GEA Group |

|

9.3. Krones AG |

|

9.4. SPX FLOW, Inc. |

|

9.5. Ishida Co., Ltd. |

|

9.6. Becton Dickinson and Company (BD) |

|

9.7. Seidenader Maschinenbau GmbH |

|

9.8. Robert Bosch GmbH |

|

9.9. Marchesini Group S.p.A. |

|

9.10. KHS GmbH |

|

9.11. Steriline Srl |

|

9.12. Asept Pak |

|

9.13. Graco Inc. |

|

9.14. Syntegon Technology GmbH |

|

9.15. Omron Corporation |

|

10. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Aseptic Processing Market. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Aseptic Processing Market. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Aseptic Processing Market. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA