As per Intent Market Research, the Alloy Market for Automotive was valued at USD 53.8 Billion in 2024-e and will surpass USD 83.7 Billion by 2030; growing at a CAGR of 7.6% during 2025-2030.

The automotive alloy market plays a pivotal role in the automotive industry, contributing significantly to vehicle performance, safety, and fuel efficiency. Alloys, particularly aluminum, steel, magnesium, and zinc alloys, are crucial for manufacturing various vehicle components such as engine parts, chassis, and structural elements. The growing demand for lightweight vehicles, along with stringent regulatory standards on fuel efficiency and emissions, has led to an increased preference for alloys in vehicle production. Furthermore, the shift toward electric vehicles (EVs) has added a new dimension to the alloy market, with a higher demand for materials that support the unique needs of electric powertrains and battery systems.

The alloy market is segmented by alloy type, application, vehicle type, and end-use industry. Among these, aluminum alloys are the most widely used in the automotive sector due to their lightweight nature, corrosion resistance, and excellent strength-to-weight ratio. The use of magnesium and zinc alloys is also on the rise, particularly in applications that require even lighter materials or enhanced durability. This market is experiencing continuous growth as manufacturers look to enhance vehicle performance, reduce carbon emissions, and meet consumer demand for energy-efficient and sustainable vehicles.

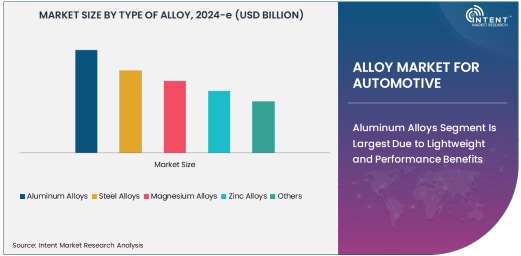

Aluminum Alloys Segment Is Largest Due to Lightweight and Performance Benefits

Aluminum alloys dominate the automotive alloy market, owing to their exceptional properties that make them ideal for a wide range of automotive applications. Aluminum is lightweight, which contributes to reduced vehicle weight, improved fuel efficiency, and lower emissions. It also offers excellent corrosion resistance and is highly formable, making it a versatile material for both structural and exterior vehicle components. As automakers strive to meet strict environmental regulations and consumer demand for better fuel economy, aluminum alloys have become the material of choice for many applications, particularly in engine components, chassis, and body parts.

The increasing adoption of aluminum alloys can also be attributed to advancements in alloy design and manufacturing technologies, which have improved the strength and durability of aluminum, making it suitable for more demanding automotive applications. Aluminum's use in electric vehicles (EVs) is also growing rapidly due to its ability to improve battery range and overall vehicle efficiency. As a result, the aluminum alloys segment is expected to maintain its position as the largest and most dominant subsegment within the automotive alloy market.

Steel Alloys Segment Is Fastest Growing Due to Strength and Durability

The steel alloys segment is the fastest-growing in the automotive alloy market, driven by the increasing demand for high-strength steel alloys in vehicle manufacturing. Steel is known for its durability, strength, and cost-effectiveness, making it a popular choice for critical components that must withstand high stress, such as transmission parts, chassis, and safety features like crash structures. The growing demand for safety and performance in vehicles, coupled with the need for cost-effective production, has led to a surge in the use of advanced high-strength steel (AHSS) in automotive applications.

Steel alloys are being increasingly used in the production of vehicle bodies and structural parts as they offer enhanced strength without significantly compromising weight. The development of newer, lighter steel alloys, such as advanced high-strength steels, is further fueling the growth of this segment. These innovations allow manufacturers to achieve the necessary strength and safety characteristics while still addressing the need for fuel-efficient vehicles. As automakers continue to focus on improving vehicle safety and performance while maintaining cost efficiency, steel alloys are expected to experience rapid growth, positioning them as the fastest-growing segment in the automotive alloy market.

Engine Components Segment Is Largest Application Due to Critical Role in Vehicle Performance

The engine components application is the largest segment in the automotive alloy market, driven by the crucial role these components play in vehicle performance, efficiency, and emissions control. Alloys, particularly aluminum and steel, are widely used in the manufacturing of engine components such as pistons, cylinder heads, crankshafts, and engine blocks. These alloys help optimize engine performance by providing the necessary strength, heat resistance, and lightweight properties to reduce fuel consumption and improve power output.

Aluminum alloys, in particular, are favored in engine components due to their lightweight nature, which helps improve fuel efficiency and reduce carbon emissions. Additionally, the demand for advanced engine technologies that enhance performance and meet regulatory requirements for fuel economy and emissions is driving the continued use of high-quality alloys in engine manufacturing. As the automotive industry focuses on delivering more fuel-efficient, high-performance vehicles, the engine components segment will remain the largest application for automotive alloys.

Passenger Vehicles Segment Is Largest Vehicle Type Due to Mass Adoption of Lightweight Materials

Passenger vehicles represent the largest vehicle type in the automotive alloy market, as the demand for lightweight materials in this segment is essential for improving fuel efficiency, reducing emissions, and enhancing overall vehicle performance. As consumer preferences shift towards fuel-efficient and environmentally friendly vehicles, automakers are increasingly incorporating alloys such as aluminum, steel, and magnesium to meet these needs. Alloys are used extensively in various parts of passenger vehicles, including engine components, chassis, body panels, and interior parts.

Passenger vehicles are the most significant consumers of lightweight materials, as the growing emphasis on reducing fuel consumption and improving driving dynamics has made alloy-based components increasingly popular. The trend towards electric vehicles (EVs), which are often lighter than traditional internal combustion engine (ICE) vehicles, has further contributed to the demand for alloys in this segment. As passenger vehicle production continues to rise globally, especially in emerging markets, the use of automotive alloys will continue to expand, ensuring that this segment remains the largest in the alloy market.

OEMs Segment Is Largest End-User Due to Direct Integration in Vehicle Production

Original Equipment Manufacturers (OEMs) are the largest end-users of automotive alloys, as they directly integrate these materials into vehicle production. OEMs are responsible for the mass production of vehicles, and the use of alloys in manufacturing is essential for achieving the desired performance, safety, and regulatory compliance. The demand for lightweight materials such as aluminum alloys in the OEM sector is particularly strong, as automakers aim to meet increasingly stringent fuel efficiency and emissions standards.

OEMs work closely with alloy suppliers to source materials that meet the specifications required for various automotive components, including engines, chassis, and body parts. The constant innovation in alloy production and the adoption of new, high-performance materials further fuel the demand in this segment. As the automotive industry continues to evolve with the rise of electric and hybrid vehicles, OEMs will remain the primary drivers of the demand for automotive alloys.

Asia-Pacific Region is Largest Region Due to Manufacturing Strength and Growth in Vehicle Production

The Asia-Pacific region is the largest in the automotive alloy market, driven by its dominant position in global automotive manufacturing and the growing production of vehicles, particularly in countries like China, Japan, and India. The region is home to several leading automotive manufacturers and has witnessed rapid growth in vehicle production, particularly in the passenger and commercial vehicle segments. As the demand for lightweight, fuel-efficient, and high-performance vehicles rises in the region, the use of alloys such as aluminum, steel, and magnesium in automotive manufacturing is also increasing.

In addition to the manufacturing strength, the Asia-Pacific region is seeing an increasing adoption of electric vehicles, which require advanced alloy materials for improved battery efficiency and performance. The growing trend towards sustainability and energy-efficient transportation in countries like China is further contributing to the demand for alloys. As vehicle production continues to rise and the automotive industry embraces more sustainable practices, the Asia-Pacific region will remain the largest market for automotive alloys.

Competitive Landscape: Leading Companies and Market Dynamics

The automotive alloy market is highly competitive, with several leading companies playing a significant role in the supply and development of alloy materials for the automotive industry. Prominent players include Alcoa Corporation, ArcelorMittal, Norsk Hydro, United States Steel Corporation, and Magnesium Elektron. These companies are focused on advancing alloy technologies, improving material properties, and developing new alloys that meet the evolving needs of the automotive industry.

The competitive landscape is characterized by continuous innovation, with companies investing heavily in research and development to create lighter, stronger, and more cost-effective alloys. Strategic partnerships between alloy manufacturers and automotive OEMs are also common, as they aim to optimize the use of alloys in vehicle production. As the market continues to evolve, the competition among key players will intensify, with a focus on sustainability, performance, and cost efficiency.

Recent Developments:

- Alcoa Corporation launched a new aluminum alloy designed to improve fuel efficiency in automotive applications.

- ArcelorMittal S.A. expanded its steel alloy production capabilities to meet the increasing demand for lightweight automotive components.

- Novelis Inc. announced a partnership with major automotive manufacturers to supply high-strength aluminum alloys for electric vehicles.

- POSCO Co., Ltd. introduced a new steel alloy to improve crash safety and overall vehicle durability.

- Thyssenkrupp AG developed an innovative magnesium alloy to reduce weight in automotive structural parts.

List of Leading Companies:

- Alcoa Corporation

- ArcelorMittal S.A.

- Tata Steel Limited

- JFE Steel Corporation

- Novelis Inc.

- UACJ Corporation

- Aleris Corporation

- Norsk Hydro ASA

- Constellium N.V.

- POSCO Co., Ltd.

- Reliance Steel & Aluminum Co.

- Kaiser Aluminum Corporation

- Thyssenkrupp AG

- Hyundai Steel Company

- China Steel Corporation

Report Scope:

|

Report Features |

Description |

|

Market Size (2024-e) |

USD 53.8 Billion |

|

Forecasted Value (2030) |

USD 83.7 Billion |

|

CAGR (2025 – 2030) |

7.6% |

|

Base Year for Estimation |

2024-e |

|

Historic Year |

2023 |

|

Forecast Period |

2025 – 2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

Alloy Market for Automotive By Type of Alloy (Aluminum Alloys, Steel Alloys, Magnesium Alloys, Zinc Alloys), By Application (Engine Components, Transmission Components, Chassis and Structural Parts, Exterior Body Parts, Interior Components), By Vehicle Type (Passenger Vehicles, Commercial Vehicles, Electric Vehicles), By End-Use Industry (OEM: Original Equipment Manufacturers, Aftermarket) |

|

Regional Analysis |

North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, Australia, India, and Rest of Asia-Pacific), Latin America (Brazil, Argentina, and Rest of Latin America), Middle East & Africa (Saudi Arabia, UAE, Rest of Middle East & Africa) |

|

Major Companies |

Alcoa Corporation, ArcelorMittal S.A., Tata Steel Limited, JFE Steel Corporation, Novelis Inc., UACJ Corporation, Aleris Corporation, Norsk Hydro ASA, Constellium N.V., POSCO Co., Ltd., Reliance Steel & Aluminum Co., Kaiser Aluminum Corporation, Thyssenkrupp AG, Hyundai Steel Company, China Steel Corporation |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements |

|

1. Introduction |

|

1.1. Market Definition |

|

1.2. Scope of the Study |

|

1.3. Research Assumptions |

|

1.4. Study Limitations |

|

2. Research Methodology |

|

2.1. Research Approach |

|

2.1.1. Top-Down Method |

|

2.1.2. Bottom-Up Method |

|

2.1.3. Factor Impact Analysis |

|

2.2. Insights & Data Collection Process |

|

2.2.1. Secondary Research |

|

2.2.2. Primary Research |

|

2.3. Data Mining Process |

|

2.3.1. Data Analysis |

|

2.3.2. Data Validation and Revalidation |

|

2.3.3. Data Triangulation |

|

3. Executive Summary |

|

3.1. Major Markets & Segments |

|

3.2. Highest Growing Regions and Respective Countries |

|

3.3. Impact of Growth Drivers & Inhibitors |

|

3.4. Regulatory Overview by Country |

|

4. Alloy Market for Automotive, by Type of Alloy (Market Size & Forecast: USD Million, 2023 – 2030) |

|

4.1. Aluminum Alloys |

|

4.2. Steel Alloys |

|

4.3. Magnesium Alloys |

|

4.4. Zinc Alloys |

|

4.5. Others |

|

5. Alloy Market for Automotive, by Application (Market Size & Forecast: USD Million, 2023 – 2030) |

|

5.1. Engine Components |

|

5.2. Transmission Components |

|

5.3. Chassis and Structural Parts |

|

5.4. Exterior Body Parts |

|

5.5. Interior Components |

|

6. Alloy Market for Automotive, by Vehicle Type (Market Size & Forecast: USD Million, 2023 – 2030) |

|

6.1. Passenger Vehicles |

|

6.2. Commercial Vehicles |

|

6.3. Electric Vehicles |

|

7. Alloy Market for Automotive, by End-Use Industry (Market Size & Forecast: USD Million, 2023 – 2030) |

|

7.1. OEM (Original Equipment Manufacturers) |

|

7.2. Aftermarket |

|

8. Regional Analysis (Market Size & Forecast: USD Million, 2023 – 2030) |

|

8.1. Regional Overview |

|

8.2. North America |

|

8.2.1. Regional Trends & Growth Drivers |

|

8.2.2. Barriers & Challenges |

|

8.2.3. Opportunities |

|

8.2.4. Factor Impact Analysis |

|

8.2.5. Technology Trends |

|

8.2.6. North America Alloy Market for Automotive, by Type of Alloy |

|

8.2.7. North America Alloy Market for Automotive, by Application |

|

8.2.8. North America Alloy Market for Automotive, by Vehicle Type |

|

8.2.9. North America Alloy Market for Automotive, by End-Use Industry |

|

8.2.10. By Country |

|

8.2.10.1. US |

|

8.2.10.1.1. US Alloy Market for Automotive, by Type of Alloy |

|

8.2.10.1.2. US Alloy Market for Automotive, by Application |

|

8.2.10.1.3. US Alloy Market for Automotive, by Vehicle Type |

|

8.2.10.1.4. US Alloy Market for Automotive, by End-Use Industry |

|

8.2.10.2. Canada |

|

8.2.10.3. Mexico |

|

*Similar segmentation will be provided for each region and country |

|

8.3. Europe |

|

8.4. Asia-Pacific |

|

8.5. Latin America |

|

8.6. Middle East & Africa |

|

9. Competitive Landscape |

|

9.1. Overview of the Key Players |

|

9.2. Competitive Ecosystem |

|

9.2.1. Level of Fragmentation |

|

9.2.2. Market Consolidation |

|

9.2.3. Product Innovation |

|

9.3. Company Share Analysis |

|

9.4. Company Benchmarking Matrix |

|

9.4.1. Strategic Overview |

|

9.4.2. Product Innovations |

|

9.5. Start-up Ecosystem |

|

9.6. Strategic Competitive Insights/ Customer Imperatives |

|

9.7. ESG Matrix/ Sustainability Matrix |

|

9.8. Manufacturing Network |

|

9.8.1. Locations |

|

9.8.2. Supply Chain and Logistics |

|

9.8.3. Product Flexibility/Customization |

|

9.8.4. Digital Transformation and Connectivity |

|

9.8.5. Environmental and Regulatory Compliance |

|

9.9. Technology Readiness Level Matrix |

|

9.10. Technology Maturity Curve |

|

9.11. Buying Criteria |

|

10. Company Profiles |

|

10.1. Alcoa Corporation |

|

10.1.1. Company Overview |

|

10.1.2. Company Financials |

|

10.1.3. Product/Service Portfolio |

|

10.1.4. Recent Developments |

|

10.1.5. IMR Analysis |

|

*Similar information will be provided for other companies |

|

10.2. ArcelorMittal S.A. |

|

10.3. Tata Steel Limited |

|

10.4. JFE Steel Corporation |

|

10.5. Novelis Inc. |

|

10.6. UACJ Corporation |

|

10.7. Aleris Corporation |

|

10.8. Norsk Hydro ASA |

|

10.9. Constellium N.V. |

|

10.10. POSCO Co., Ltd. |

|

10.11. Reliance Steel & Aluminum Co. |

|

10.12. Kaiser Aluminum Corporation |

|

10.13. Thyssenkrupp AG |

|

10.14. Hyundai Steel Company |

|

10.15. China Steel Corporation |

|

11. Appendix |

A comprehensive market research approach was employed to gather and analyze data on the Alloy Market for Automotive. In the process, the analysis was also done to analyze the parent market and relevant adjacencies to measure the impact of them on the Alloy Market for Automotive. The research methodology encompassed both secondary and primary research techniques, ensuring the accuracy and credibility of the findings.

.jpg)

Secondary Research

Secondary research involved a thorough review of pertinent industry reports, journals, articles, and publications. Additionally, annual reports, press releases, and investor presentations of industry players were scrutinized to gain insights into their market positioning and strategies.

Primary Research

Primary research involved conducting in-depth interviews with industry experts, stakeholders, and market participants across the E-Waste Management ecosystem. The primary research objectives included:

- Validating findings and assumptions derived from secondary research

- Gathering qualitative and quantitative data on market trends, drivers, and challenges

- Understanding the demand-side dynamics, encompassing end-users, component manufacturers, facility providers, and service providers

- Assessing the supply-side landscape, including technological advancements and recent developments

Market Size Assessment

A combination of top-down and bottom-up approaches was utilized to analyze the overall size of the Alloy Market for Automotive. These methods were also employed to assess the size of various subsegments within the market. The market size assessment methodology encompassed the following steps:

- Identification of key industry players and relevant revenues through extensive secondary research

- Determination of the industry's supply chain and market size, in terms of value, through primary and secondary research processes

- Calculation of percentage shares, splits, and breakdowns using secondary sources and verification through primary sources

.jpg)

Data Triangulation

To ensure the accuracy and reliability of the market size, data triangulation was implemented. This involved cross-referencing data from various sources, including demand and supply side factors, market trends, and expert opinions. Additionally, top-down and bottom-up approaches were employed to validate the market size assessment.

NA