sales@intentmarketresearch.com

+1 463-583-2713

Powder Handling Equipment Market Size Analysis, By Equipment (Vibratory Feeders, Bucket Elevators, Pneumatic Conveying, Bulk Bag Discharger, Flexible Screw Conveyors), By Application (Filling, Loading, Refilling, Sealing, Packaging), By Industry (Pharmaceutical, Food, Chemical, Cement) and Region; Global Insights & Forecast (2024 - 2030)

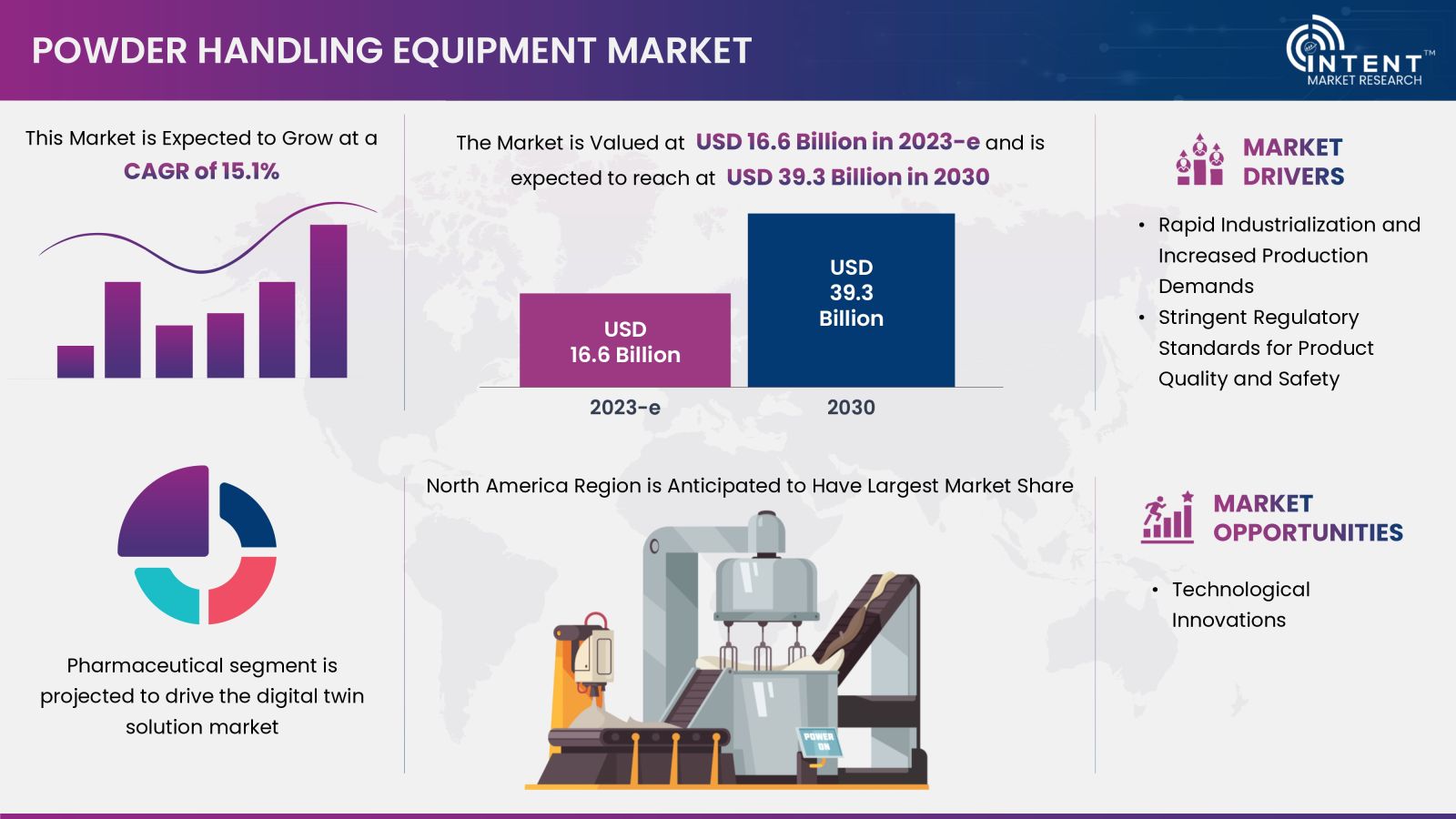

As per Intent Market Research, the Powder Handling Equipment Market was valued at USD 16.6 billion in 2023-e and will surpass USD 39.3 billion by 2030; growing at a CAGR of 15.1% during 2024 - 2030. Mixing, packaging, and sealing applications in the pharmaceutical industry are driving the growth of the powder handling equipment market.

Powder handling equipment are designed to transport and deliver powder materials to various equipment within a processing plant, whether they are raw minerals, pharmaceutical powders, or chemicals. These systems facilitate the movement of materials from filling, and storage to mixing, dosing, discharging, and packaging. The fundamental processing technologies incorporated in these systems encompass a range of operations, including lifting, size reduction, mixing, separating, weighing, and filling.

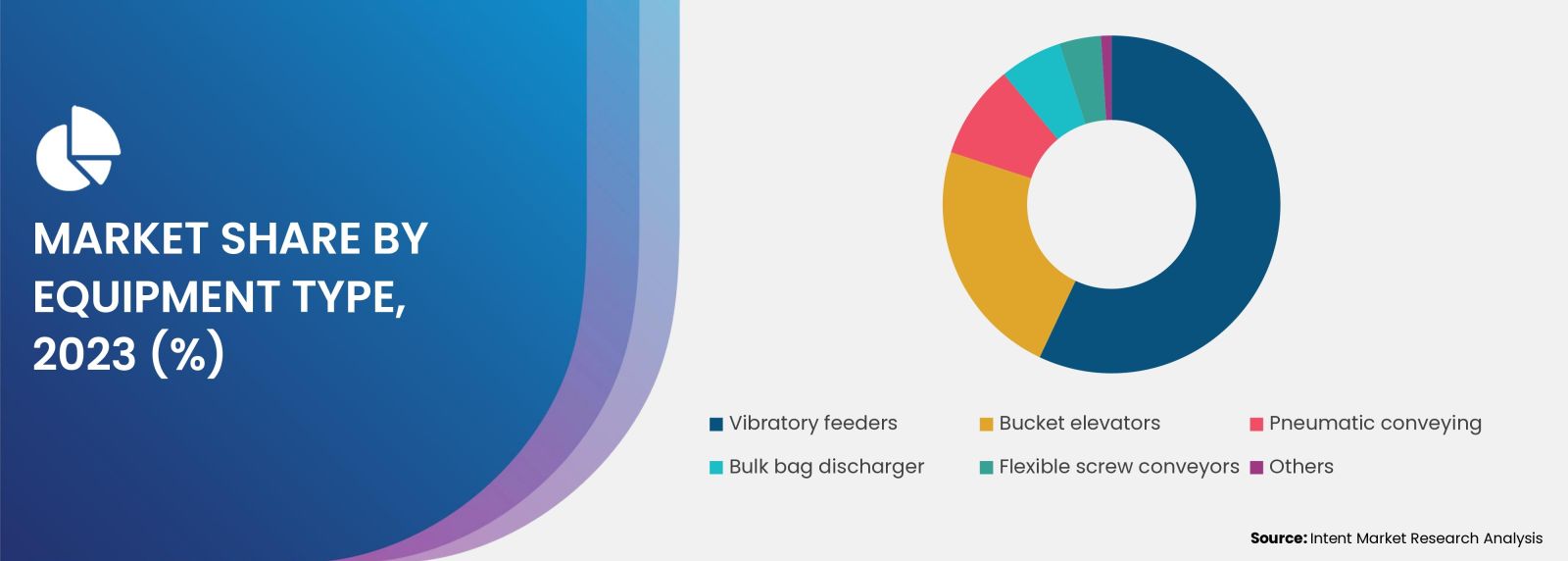

Growing technological advancements and automation trends is expected to fuel the growth in the powder handling equipment market. These equipment are designed for efficiency, flexibility and safety. Innovations in powder handling equipment, such as vibratory feeders, bucket elevators, pneumatic conveying, bulk bag dischargers, and flexible screw conveyors, have been pivotal in streamlining processes.

The integration of advanced technologies has led to reduced manual intervention, enhanced accuracy in material control, and improved overall operational performance. Automation has played a crucial role in optimizing powder handling systems. With the implementation of sophisticated control systems and sensors, these systems can now adapt to varying production demands, ensuring a seamless and consistent flow of powders throughout the manufacturing process.

Rapid industrialization and increased production demand aid market growth

The global push towards industrialization, particularly in emerging economies, aids in the demand for powder-handling equipment. A growing need for efficient and automated systems to handle powdered materials and increase production volume is projected to fuel industry growth. The growth of pharmaceuticals, chemicals, and processed food industries and the increasing adoption of powder-handling solutions in them is projected to fuel market growth.

Stringent regulatory standards and quality requirements for product quality and safety propel the market growth

Regulatory bodies worldwide are placing a greater emphasis on product quality and safety standards. Increasing regulatory standards and a growing emphasis on product quality and safety drive the adoption of advanced powder handling technologies. Industries such as pharmaceuticals, food, and chemicals, must adhere to strict guidelines to ensure the integrity and purity of their products.

Powder-handling equipment with features such as containment systems and dust control becomes essential for compliance with these regulations. For instance, in pharmaceutical manufacturing, where even minor deviations can have significant consequences, the adoption of handling powder-handling solutions becomes imperative.

Impact of COVID-19 on Powder Handling Equipment Market

The COVID-19 pandemic has had a significant impact on the powder handling equipment market, particularly within the pharmaceutical sector. The global crisis prompted pharmaceutical companies to fortify their operations and respond to the heightened demand for medical supplies. As a result, there has been a surge in the construction of additional production facilities, leading to an increased demand for powder handling equipment.

One key factor contributing to the growth of the powder handling equipment market is the emphasis on product development within the pharmaceutical industry. With the urgent need for the manufacturing and distribution of vaccines, medications, and other healthcare products, pharmaceutical companies are investing in advanced powder handling technologies to enhance their production capabilities.

As pharmaceutical companies continue to adapt to the challenges posed by the pandemic, the powder handling equipment market is expected to experience sustained growth. The increased awareness of the importance of reliable and hygienic powder handling solutions, coupled with the ongoing demand for pharmaceutical products, positions the industry for further expansion in the post-pandemic era.

Vibratory Feeders Held the Majority of the Share in the Powder Handling Equipment Market

The vibratory feeders held the majority of the share in 2023. Vibratory feeders are commonly used for feeding and conveying powders in a controlled manner. It contributes to the seamless flow of powders in manufacturing processes, improving overall productivity and reducing waste. Vibrating feeders present numerous advantages, including lowered maintenance expenses, high productivity, and improved material handling capabilities. These attributes position them as the preferred option compared to conventional feeding equipment.

Filling Applications Across Various Industries is Anticipated to Grow at a Significant Rate During the Forecast Period

Powder handling equipment market is segmented based on application into filling, loading, refilling, sealing, packaging, and others. Filling operations are streamlined with powder handling equipment, ensuring accurate and efficient product packaging thereby holding significant share in overall powder handling equipment market. In industries such as pharmaceuticals, food, and chemicals, the filling process is critical to ensuring product quality, consistency, and compliance with regulatory standards. The powder handling equipment designed for filling applications includes a range of technologies and machinery that facilitate accurate dosing, measuring, and dispensing of powders into containers, packages, or production lines.

Pharmaceutical Industry to Have Highest CAGR to Prevent of Any Form of Contamination

Powder handling equipment market end-use industries, includes pharmaceutical, food, chemical, cement, and others. The pharmaceutical industry demands precise and stringent control over dosage accuracy and contamination prevention during the production of medications. Powder handling equipment proves to be indispensable in achieving these crucial objectives. In pharmaceutical manufacturing, where the formulation and composition of drugs are highly regulated, the accuracy of dosing and the prevention of any form of contamination are of paramount importance to ensure the efficacy and safety of the final products.

North America to Register High Growth Throughout the Forecast Period

North American powder handling equipment market is anticipated to register high growth throughout the forecast period. The market growth is attributed to innovative technological development. The diverse industrial landscape in North America contributes to the demand for powder handling equipment market across multiple sectors. Industries such as pharmaceuticals, food, chemical, cement have substantial requirements for precise powder handling solutions. North American industry is projected to grow as a result of an ageing population and need for faster, more accurate medication services.

The Acquisition of Smaller Players and Product Innovations by Major Players are Driving the Market Growth

The powder handling equipment market is characterized by intense competition due to the presence of numerous international and domestic players. The powder handling equipment market, in particular, is dominated by key players such as THIELMANN, Schenck, Coperion, BEUMER Group, Dematic, Buhler Group, Matcon (IDEX), Tetra Pak, Spiroflow, and Flexicon. These industry leaders are primarily focused on acquiring smaller players and innovating their product lines to cater to the powder-handling market.

- In April 2023, Tetra Pak introduced powder handling equipment "Tetra Pak Bag Tipping unit SA VS800" which is an automatic bag opening solution that can double the manual processes

- In July 2022, Spiroflow added Cablevey Tubular Drag Conveyors to its portfolio

- In April 2021, ILC Dover introduced a flexible aseptic isolator for the pharma and biopharma industry. It is a cost-effective, closed-barrier system for sterile manufacturing

- In January 2021, Volkmann USA announced the launch of a twin bulk bag unloader (BBU) which is developed to boost powder handling efficiency and save floor space

Powder Handling Equipment Market Coverage

The report provides key insights into the powder handling equipment market, and it focuses on technological developments, trends, and initiatives taken by the government in this sector. The focus extends to market drivers, restraints, opportunities, and an analysis of key players and the competitive landscape within the powder handling equipment market. The report offers the market size and forecasts for the powder handling equipment market in value (USD billion) for all the below segments

Report Scope

|

Report Features |

Description |

|

Market Size (2023-e) |

USD 16.6 billion |

|

Forecast Revenue (2030) |

USD 39.3 billion |

|

CAGR (2024-2030) |

15.1% |

|

Base Year for Estimation |

2023-e |

|

Historic Year |

2022 |

|

Forecast Period |

2024-2030 |

|

Report Coverage |

Market Forecast, Market Dynamics, Competitive Landscape, Recent Developments |

|

Segments Covered |

By Equipment (Vibratory Feeders, Bucket Elevators, Pneumatic Conveying, Bulk Bag Discharger, Flexible Screw Conveyors), By Application (Filling, Loading, Refilling, Sealing, Packaging), By Industry (Pharmaceutical, Food, Chemical, Cement) |

|

Regional Analysis |

North America (US, Canada), Europe (Germany, France, UK, Spain, Italy), Asia Pacific (China, Japan, South Korea, India), Latin America (Brazil, Mexico, Argentina), Middle East & Africa (Saudi Arabia, South Africa, Turkey, United Arab Emirates) |

|

Competitive Landscape |

BEUMER Group, Buhler Group, Coperion, Dematic, Flexicon, Matcon (IDEX), Schenck, Spiroflow, Tetra Pak, and THIELMANN |

|

Customization Scope |

Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. |

|

Purchase Options |

We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) |

|

1.Introduction |

|

1.1. Study Assumptions and Market Definition |

|

1.2. Scope of the Study |

|

2.Research Methodology |

|

3.Executive Summary |

|

4.Market Dynamics |

|

4.1. Market Growth Drivers |

|

4.1.1. Rapid Industrialization and Increased Production Demands |

|

4.1.2. Stringent Regulatory Standards for Product Quality and Safety |

|

4.1.3. Technological Advancements and Automation Trends |

|

4.2. Market Growth Challenges |

|

4.2.1. High Initial Investment Costs |

|

4.2.2. Maintenance and Operational Challenges |

|

4.3. Market Growth Opportunities |

|

4.3.1. Technological Innovations |

|

5.Market Outlook |

|

5.1. Overview (Industry Snapshot) |

|

5.2. Impact of COVID-19 |

|

5.3. Market Opportunity & Funding Analysis |

|

5.4. Powder Handling Market Trends |

|

5.5. Value-Chain Analysis |

|

5.6. Supply Chain Analysis |

|

5.7. Regulatory Framework |

|

5.8. Technology and Innovation Landscape |

|

5.9. Industry Ecosystem Analysis (Raw Material, Service Provider, Vendor, And Manufacture Others) |

|

6.Market Segment Outlook (Market Size & Forecast: USD Billion, 2024 – 2030) |

|

6.1.Segment Synopsis |

|

6.2.By Equipment Type |

|

6.2.1. Vibratory Feeders |

|

6.2.2. Bucket Elevators |

|

6.2.3. Pneumatic Conveying |

|

6.2.4. Bulk Bag Discharger |

|

6.2.5. Flexible Screw Conveyors |

|

6.2.6. Others |

|

6.3. By Industry |

|

6.3.1. Pharmaceutical |

|

6.3.2. Food |

|

6.3.3. Chemical |

|

6.3.4. Cement |

|

6.3.5. Others |

|

6.4. By Application |

|

6.4.1. Filling |

|

6.4.2. Loading |

|

6.4.3. Refilling |

|

6.4.4. Sealing |

|

6.4.5. Packaging |

|

6.4.6. Others |

|

7.Regional Outlook (Market Size & Forecast: USD Billion, 2024 – 2030) |

|

7.1. Global Market Synopsis |

|

7.2. North America |

|

7.2.1. North America Powder Handling Market Outlook |

|

7.2.2. US |

|

7.2.2.1.US Powder Handling Market, By Equipment |

|

7.2.2.2.US Powder Handling Market, By Industry Type |

|

7.2.2.3.US Powder Handling Market, By Application |

|

*Note: Cross-segmentation by segments for each country will be covered as shown above. |

|

7.2.3. Canada |

|

7.3. Europe |

|

7.3.1. Europe Powder Handling Market Outlook |

|

7.3.2. Germany |

|

7.3.3. UK |

|

7.3.4. France |

|

7.3.5. Spain |

|

7.3.6. Italy |

|

7.4. Asia-Pacific |

|

7.4.1. Asia-Pacific Powder Handling Market Outlook |

|

7.4.2. China |

|

7.4.3. India |

|

7.4.4. Japan |

|

7.4.5. South Korea |

|

7.4.6. Australia |

|

7.5. Latin America |

|

7.5.1. Latin America Powder Handling Market Outlook |

|

7.5.2. Mexico |

|

7.5.3. Brazil |

|

7.6. Middle East & Africa |

|

7.6.1. Middle East & Africa Powder Handling Market Outlook |

|

7.6.2. Saudi Arabia |

|

7.6.3. UAE |

|

8.Competitive Landscape |

|

8.1. Market Share Analysis |

|

8.2. Volume Output Analysis |

|

8.3. Company Strategy Analysis |

|

8.4. Competitive Matrix |

|

9.Company Profiles |

|

9.1.BEUMER Group |

|

9.1.1. Company Synopsis |

|

9.1.2. Company Financials |

|

9.1.3. Product/Service Portfolio |

|

9.1.4. Recent Developments |

|

9.1.5. Analyst Perception |

|

*Note: All the companies in the section 9.1 will cover same sub-chapters as above. |

|

9.2. Buhler Group |

|

9.3. Coperion |

|

9.4. Dematic |

|

9.5. Flexicon |

|

9.6. Gericke |

|

9.7. IDEX (Matcon Group) |

|

9.8. Schenck |

|

9.9. THIELMANN |

|

9.10.Tetra Pak |

|

9.11.Vortex Global |

Let us connect with you TOC

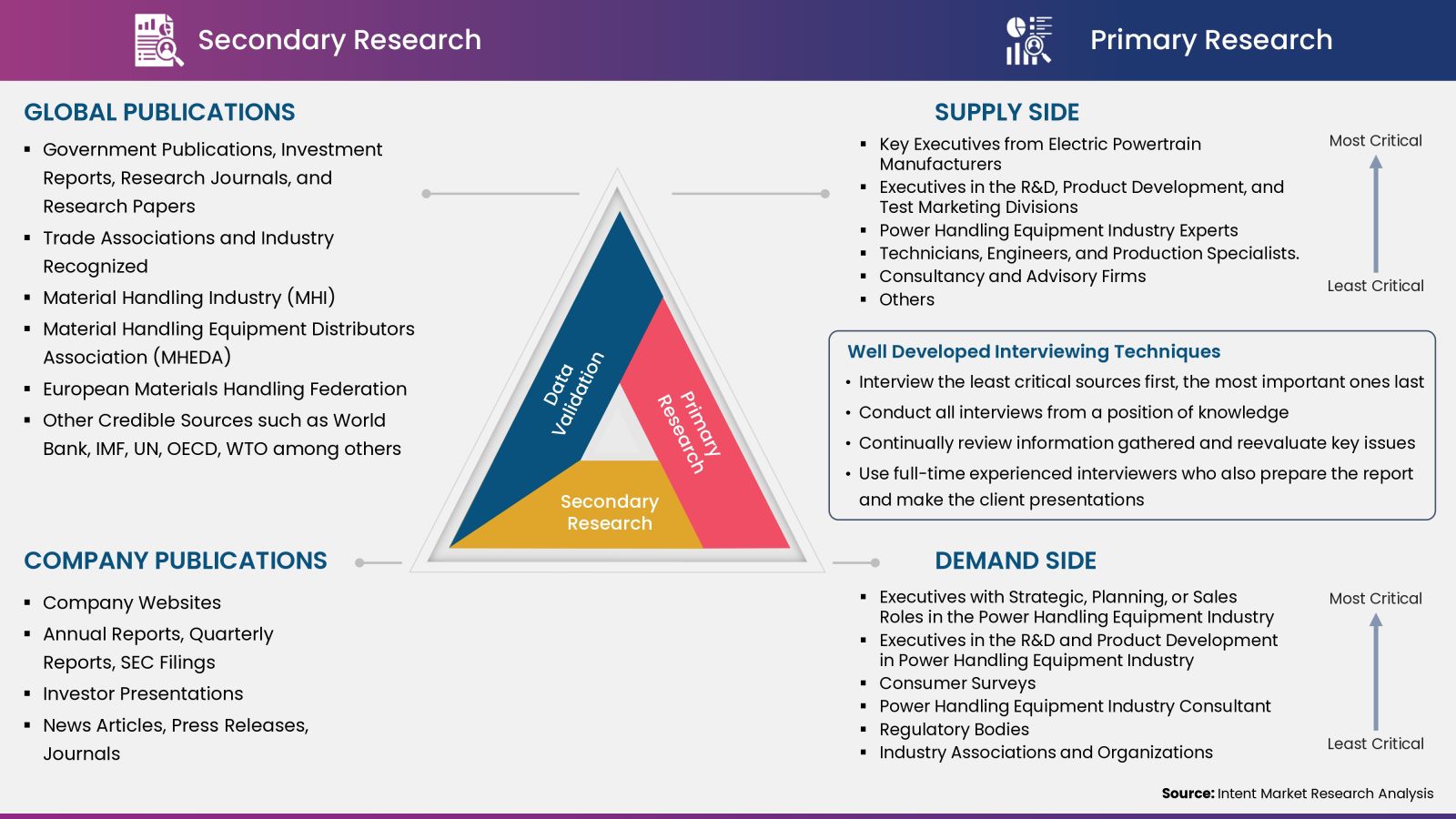

Intent Market Research employs a rigorous methodology to minimize residual errors by carefully defining the scope, validating findings through primary research, and consistently updating our in-house database. This dynamic approach allows us to capture ongoing market fluctuations and adapt to evolving market uncertainties.

The research factors used in our methodology vary depending on the specific market being analyzed. To begin with, we incorporate both demand and supply side information into our model to identify and address market gaps. Additionally, we also employ approaches such as Macro-Indicator Analysis, Factor Analysis, Value Chain-Based Sizing, and forecasting to further increase the accuracy of the numbers and validate the findings.

Research Approach

- Secondary Research Approach: During the initial phase of the research process, we acquire and accumulate extensive data continuously. This data is carefully filtered and validated through a variety of secondary sources.

- Primary Research Approach: Following the consolidation of data gathered through secondary research, we initiate a validation and verification process to verify all the market numbers and assumptions by engaging with the subject matter experts.

Data Collection, Analysis and Interpretation:

Research Methodology

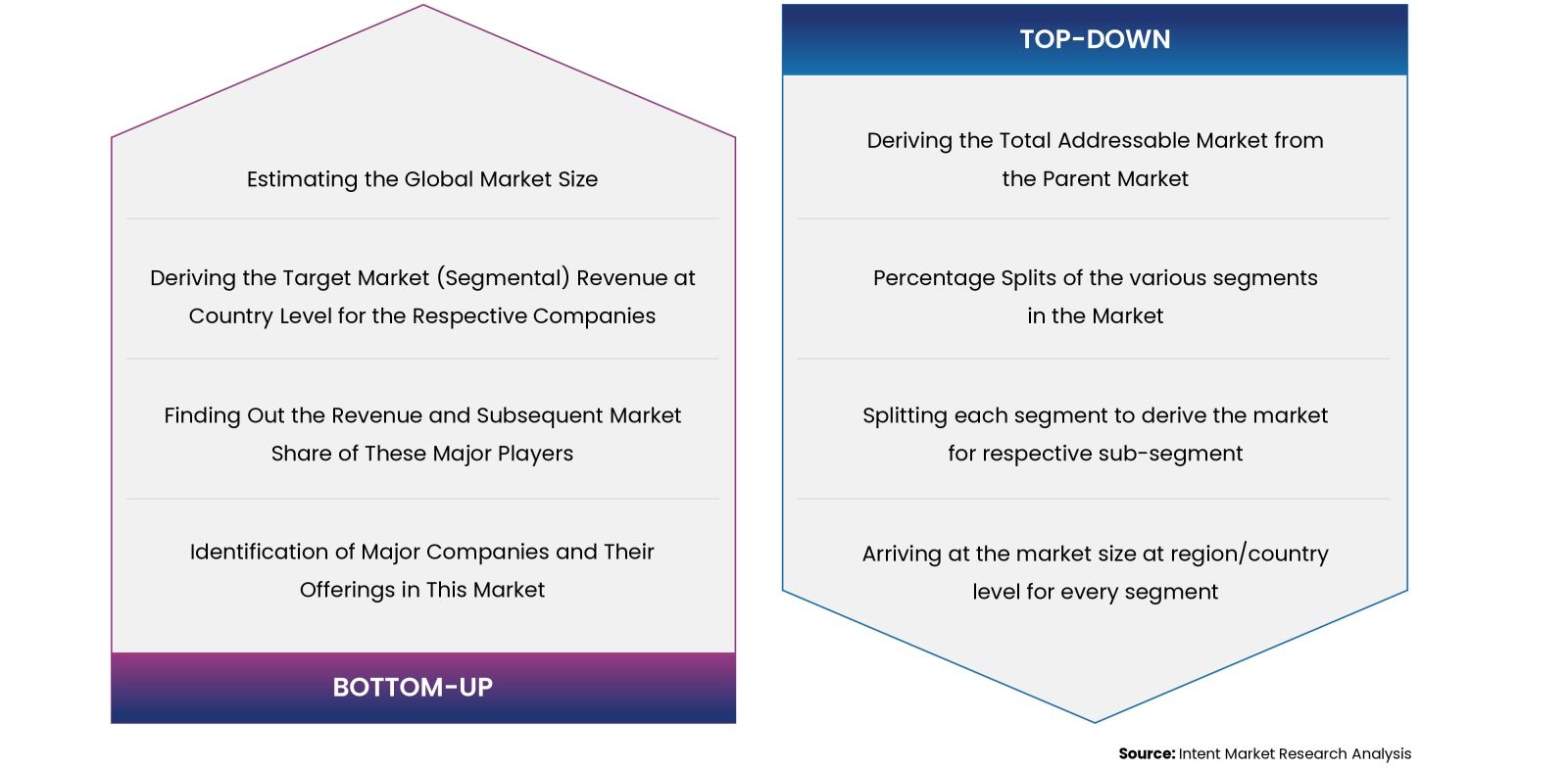

Our market research methodology utilizes both top-down and bottom-up approaches to segment and estimate quantitative aspects of the market. We also employ multi-perspective analysis, examining the market from distinct viewpoints.

Available Formats